What Is Forged Steel and How Is It Made

Forged steel is made when workers mix iron and carbon. They shape this mix using strong pressure and heat. This makes steel with even and smooth grains. Cast or rolled steel does not have this grain structure. Forged steel is stronger and tougher. It has fewer problems inside the metal. The forging process lines up the grains with the part’s shape. This helps the steel last longer and work better.

Category | Volume (million metric tons) | Notes |

|---|---|---|

Global steel production | About this much steel is made each year | |

Forging and casting combined | 300 | This much steel is shaped by forging or casting |

Estimated forged steel % | ~15% | Forged steel is part of the 300 million tons |

Forged steel is used for parts that must be strong. It is needed in places where things wear out easily.

Forged Steel Overview

What Is Forged Steel

Forged steel is made by mixing iron and carbon. Workers heat the steel until it gets soft. They use tools to press or hammer it into shape. This process changes how the steel looks inside. It makes the steel stronger and more dependable.

The chemical makeup of forged steel depends on its grade. Most forged steel has iron as the main part. Carbon is the key element added to it. The amount of carbon changes how hard and strong the steel is. More carbon makes the steel harder. Less carbon makes it easier to shape.

Steel Grade | Iron Content | Carbon Content (%) |

|---|---|---|

AISI 1045 | Balance | ~0.45 |

AISI 4140 | Balance | 0.38 – 0.43 |

1095 | Balance | 0.90 – 1.03 |

Most forged steel grades have between 0.20% and 1.0% carbon. This lets makers pick the right steel for each job. Steel with more carbon is used for tools and blades. Steel with less carbon is used for parts that need to bend.

Forged Steel vs. Other Steel

Forged steel is different from other steel types. It has a special grain structure and is very strong. The forging process makes the grains line up with the part’s shape. This makes the steel tougher and last longer.

Forged steel is shaped at high heat. This makes the grains flow with the part’s shape.

Grain flow gives forged steel extra toughness. The steel does not break easily along the grain lines, like wood.

Forged steel has fewer problems inside. The process removes things like trapped air and holes.

Cast steel is made by pouring melted steel into molds. The grains do not line up with the part’s shape. Cast steel often has more problems inside and is not as tough.

Rolled steel is made by rolling hot steel between rollers. This makes layers in the grain. Rolled steel is strong but not as tough as forged steel.

Forged steel is better at handling stress and heavy loads. It is more reliable than cast or rolled steel. Forged steel parts last longer and work better in tough places.

Tip: Forged steel is best for parts that must be very strong. The forging process makes the steel better inside and removes problems. This makes it great for important uses.

Forging Process

Steel Forging Methods

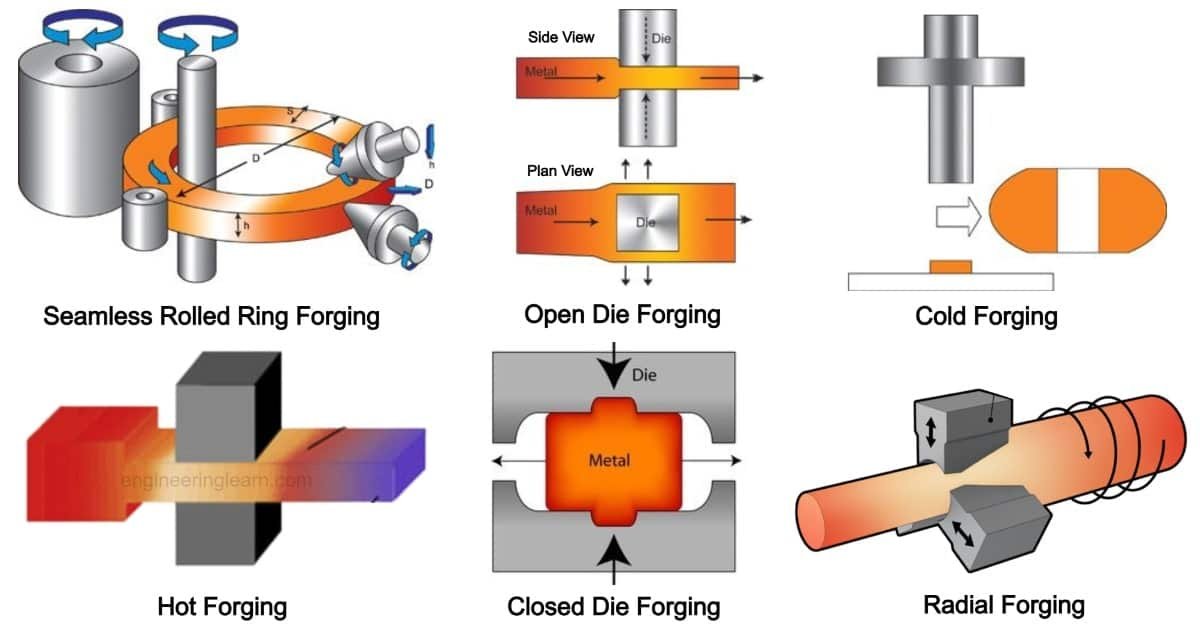

Steel forging shapes metal into strong parts. There are many ways to do this. Each way uses different tools and machines. The method chosen depends on the part’s size and shape.

Temperature Condition | Description & Applications | |

|---|---|---|

Hot Forging | Above recrystallization temp | Steel heated to improve ductility; used in open and closed die forging; reduces force needed; refines grain structure; suitable for high-load parts. |

Heated Die Forging | Heated dies (400°F-500°F) | Variation of hot forging; uses heated dies to reduce machining, improve tolerances, and control plastic flow. |

Cold Forging | Near room temperature | Forging without heating; requires higher force; improves dimensional accuracy and surface finish; used for fasteners and bolts. |

Open Die Forging | Can be hot or warm | Uses flat/simple dies; shapes large, simple components; imprecise; requires machining after forging. |

Closed Die Forging | Typically hot | Uses precisely machined dies; produces complex, repeatable parts; involves flash formation; used in automotive and aerospace. |

Roll Forging | Hot or warm | Uses rollers to elongate billets; produces axles, rings. |

Extrusion | Hot | Forces steel through a die to create uniform cross-sections; used for rods, railings. |

Upset Forging | Hot | Increases diameter of steel sections; used for bolts, screws. |

Open die forging makes big, simple parts. It uses flat dies and needs more work after. Closed die forging uses detailed dies for complex shapes. This way gives high accuracy and strong parts. Cold forging shapes steel at room temperature. It makes smooth and exact parts but works best for small things. Seamless rolled ring forging makes strong rings by rolling a donut shape. This helps the grains flow and makes the rings tough.

Note: Closed die forging is best for making many parts that must match. Open die forging is good for custom or big pieces.

Forging Method | Disadvantages | |

|---|---|---|

Impression Die Forging | High precision and close tolerances; strong mechanical properties; suitable for complex shapes. | High tooling and operating costs; expensive dies; less suitable for low volume or small runs. |

Open Die Forging | Cost-effective; flexible for large/simple shapes; suitable for various metals; low material waste. | Cannot be automated; requires skilled labor; less precision; needs post-machining; irregular shapes. |

Cold Forging | Improved dimensional accuracy; better surface finish; increased strength via strain hardening. | Limited to room temperature processing; less suitable for complex shapes or large parts. |

Seamless Rolled Ring Forging | Produces thin ring shapes with improved grain flow; enhanced fatigue and impact resistance. | Limited to ring-shaped components; specialized equipment required. |

Closed die forging is great for making complex parts that must be the same. Open die forging is cheaper and works for big, simple shapes. Cold forging makes smooth, exact parts but not big or tricky ones. Seamless rolled ring forging is best for strong, ring-shaped parts.

Role of Temperature and Pressure

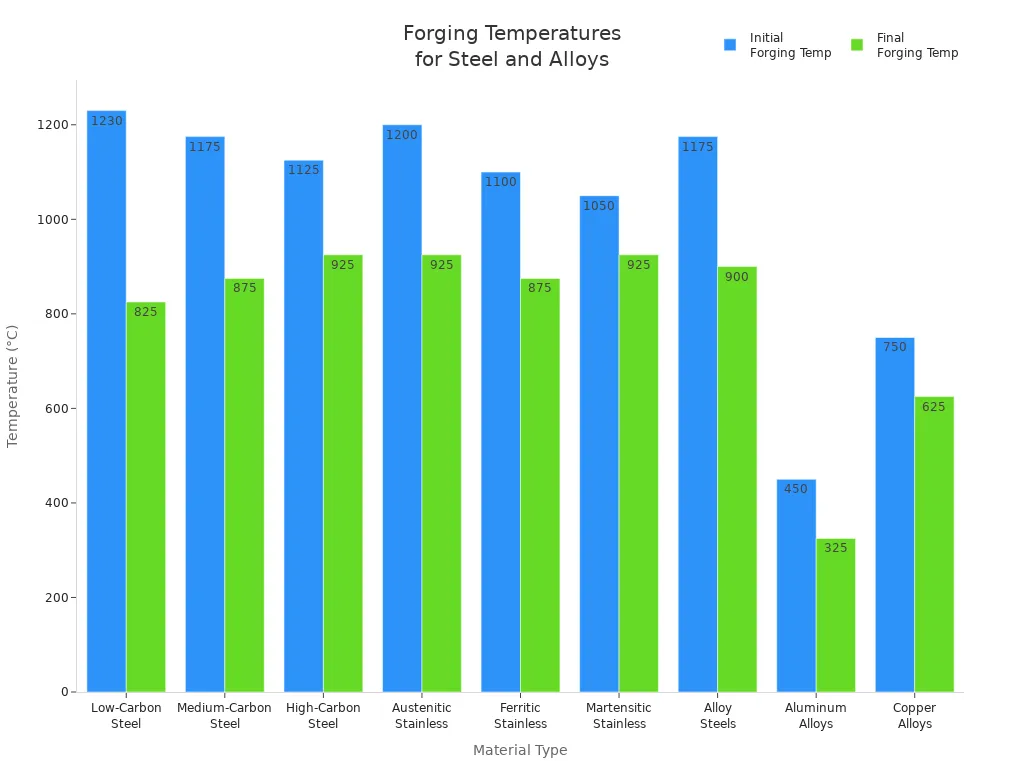

Temperature and pressure are very important in steel forging. The right heat makes steel soft and easy to shape. High pressure pushes the metal into the right form. Hot forging happens above the steel’s recrystallization temperature. This makes the grains smaller and the steel stronger.

Initial Forging Temperature (°C) | Final Forging Temperature (°C) | Effect on Properties | |

|---|---|---|---|

Low-Carbon Steel (<0.3% C) | 1200 – 1250 | ≥ 800 – 850 | Good ductility; forging below final temp causes brittleness and cracking |

Medium-Carbon Steel (0.3%-0.6% C) | 1150 – 1200 | ≥ 850 – 900 | Balanced strength and ductility; avoids hard/brittle structures |

High-Carbon Steel (>0.6% C) | 1100 – 1150 | ≥ 900 – 950 | High strength and hardness; low temp forging risks cracking |

Austenitic Stainless Steel | 1150 – 1250 | ≥ 900 – 950 | Corrosion resistance; overheating causes grain growth and property loss |

Ferritic Stainless Steel | 1050 – 1150 | ≥ 850 – 900 | Sensitive to temperature; improper temp leads to embrittlement |

Martensitic Stainless Steel | 1000 – 1100 | ≥ 900 – 950 | High strength/hardness; requires post-forging heat treatment |

Alloy Steels (e.g., Cr-Mo, Ni-Cr-Mo) | 1100 – 1250 | ≥ 850 – 950 | Precise temp control needed for phase formation and mechanical properties |

Aluminum Alloys | 400 – 500 | ≥ 300 – 350 | Low forging temp; sensitive to overheating causing grain growth |

Copper Alloys | 700 – 800 | ≥ 600 – 650 | Requires careful temp control to avoid cracking and ensure surface finish |

When the temperature is right, the grains get better. This makes forged steel stronger and less likely to crack. Too much heat makes the grains too big and weakens the steel. Too little heat can cause cracks and make the steel break easily. Pressure also matters a lot. High pressure shapes the steel and makes it stronger. The process must balance heat and pressure for the best results.

Making the forging ratio higher makes grains smaller and steel stronger.

Good forging methods help stop cracks and make steel last longer.

High forging ratios keep grains fine, but too much can hurt the steel.

Forging pressure changes how strong and tough the steel is.

Tip: Keeping the right temperature and pressure is key to making strong steel parts.

How Forged Steel Is Made

The steel forging process has clear steps from start to finish. Each step uses special ways and checks for quality.

Workers mix iron ore, coke, and limestone in a blast furnace. This makes molten iron.

They turn molten iron into steel in special furnaces. This step removes bad stuff and sets the carbon level.

The steel is cleaned more and other elements can be added.

Molten steel is poured into billets or other shapes.

Workers cut billets to size and heat them in a furnace. The right heat makes the steel soft for forging.

They shape the hot billets with forging tools and machines.

After shaping, extra material is trimmed off and the part is finished.

The forged steel part is heat treated to make it better. This can include normalizing, quenching, or tempering.

Workers clean the surface, often by blasting it with small steel balls.

Machining gives the part its final size and smoothness.

Each part is checked for quality, like cracks, hardness, and shape.

Quality control is important at every step. Workers check materials, control heat, inspect tools, and test the finished steel. They use special tools to find problems and make sure each part is good.

Steel forging uses many ways to make strong, reliable parts. Closed die forging is common for tricky shapes. Open die forging is good for big or custom pieces. Hot forged steel parts are tough and have fine grains. This process shows how forged steel is made and why it is trusted in many jobs.

Forged Steel Properties

Strength and Toughness

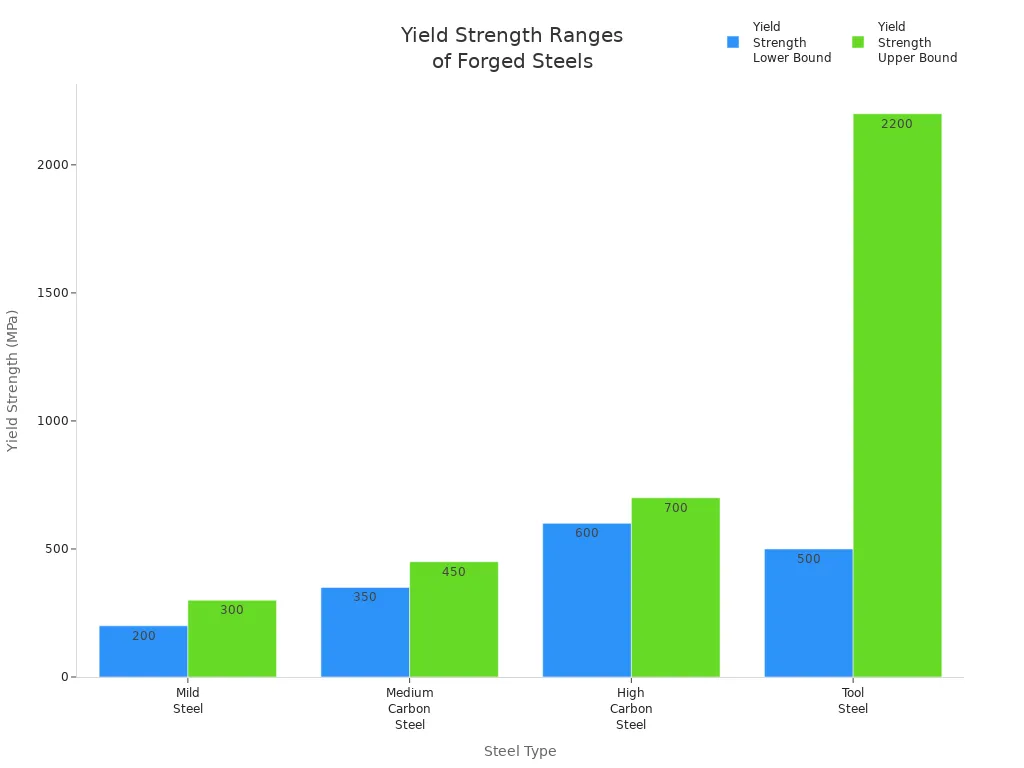

Forged parts are very strong and tough. The forging process makes steel with high tensile strength. This means it can handle hard jobs. Yield strength changes with the steel type. Mild steel has a yield strength of 200 to 300 MPa. Ultra-high-strength steels can go over 2000 MPa. Tool steels and maraging steels can also be very strong.

Steel Type | Notes | |

|---|---|---|

Mild Steel (Low-Carbon Steel) | 200 – 300 | Used for general fabrication |

Medium Carbon Steel (AISI 1045) | 350 – 450 | Used for shafts, gears, axles |

High Carbon Steel (AISI 1095) | 600 – 700 | Used in cutting tools, springs |

Tool Steel | 500 – 2200+ | Wide range depending on type and treatment |

Ultra-High-Strength Steels (UHSS) | >2000 | Used in automotive and defense |

Forged steel does well in impact tests. At room temperature, forged parts have an impact toughness of 80 to 150 J/cm². Cast steel only gets 30 to 60 J/cm². Even when it is cold, forged parts stay tough and do not break easily.

Grain Structure and Defects

Forging changes the grain structure inside steel. It breaks up big grains and makes them small and even. This helps the steel get stronger and handle stress from all sides. Forging also gets rid of many problems found in cast steel.

It removes casting problems like porosity, shrinkage holes, and trapped gas.

Forged parts have fewer empty spaces and are more solid.

Rolling can make layers and stress, but forging keeps the grain flow smooth and strong.

Note: Forged parts have a tight structure with fewer weak spots. This makes them better for heavy-duty jobs.

Ductility and Fatigue Resistance

Forged steel can bend and stretch without breaking. When tested, forged parts can stretch 15% to 20% before breaking. This is important for safety.

Property | Condition/Temper | Test Temperature | Typical Elongation Range | Test Standard |

|---|---|---|---|---|

Elongation | Quenched & Tempered | Room Temperature | 15 – 20% | ASTM E8 |

Forged parts also last longer under repeated stress. They do better than cast or rolled steel. The forging process lines up the grains and removes problems. Forged parts can handle millions of cycles without cracking. Surface treatments like shot blasting can make them even stronger.

Tip: Forged steel is great for parts that need to bend, stretch, or take repeated loads without breaking.

Steel Forging Applications

Industries Using Forged Steel

Many industries need steel forgings for key parts. The automotive industry uses the most forged steel. It makes up more than half of the world’s market. Car makers pick forged parts because they are strong and last long. These parts also save money. Strong parts help cars handle stress and stay safe. The aerospace industry also uses a lot of forged steel. Airplane makers need forged parts for wings and engines. These parts must work in tough places and hold heavy loads.

Other industries use forged steel too. Power plants, shipbuilders, oil and gas companies, and builders all need forged parts. These parts keep things safe and working well. Asia-Pacific, with China and India, leads in steel forging. This is because they build many cars and roads. More electric cars and more flights mean more forged steel is needed.

Industries like forged parts because they last, handle stress, and need less fixing.

Common Forged Steel Products

Factories make many forged steel products for different jobs. Stainless steel and carbon steel are used the most. Stainless steel forgings are used in planes, cars, food, medicine, and power plants. Carbon steel forgings are strong and tough. They are used in farming, building, and making things.

Crankshafts, connecting rods, and suspension parts for cars and trucks

Turbine blades, compressor rotors, and landing gear for aircraft

High-pressure valves, flanges, and pipelines for oil and gas

Fasteners, actuators, and hose clamps for industrial machinery

Forged Steel Product | Description | Typical Applications |

|---|---|---|

Block Forged | Steel blocks with high strength and elasticity | Chemical, food, electric engines, machining |

Forged Steel Rings | Seamless rings with solid grain flow | Aeronautics, mining, power, pressure vessels |

Cylinder Forgings | Cylinders for high-stress environments | Industrial machinery, hazardous settings |

Forged Discs | Solid discs with robust microstructure | Durable industrial uses |

Special forged products are made for jobs that need unique shapes or sizes. Closed die forging helps make these parts exact and strong.

Forged parts are known for being strong and tough. They also last a long time. The forging process lines up the grains inside the metal. This makes each part dense and dependable. Many industries use forged parts to keep things safe. Cars, planes, and big machines all need these parts to work well. There are some problems, like tools wearing out fast. Workers also must control the heat very carefully. New technology helps make better forged parts. People still pick forged parts when they need things to be strong and last long.

FAQ

What makes forged steel stronger than cast steel?

Forged steel has grains that flow with the shape of the part. This grain flow gives the steel extra strength and toughness. Cast steel does not have this grain structure, so it is usually weaker.

Can forged steel rust?

Forged steel can rust if it does not have protection. Makers often add coatings or use stainless steel to stop rust. Keeping forged steel dry and clean helps prevent rust.

Is forged steel more expensive than other steel types?

Forged steel often costs more than rolled or cast steel. The forging process uses more energy and special tools. The extra cost gives better strength and longer life.

Where do people use forged steel the most?

Car makers use forged steel for crankshafts and gears.

Airplane builders use it for landing gear and engine parts.

Oil and gas companies use it for valves and flanges.