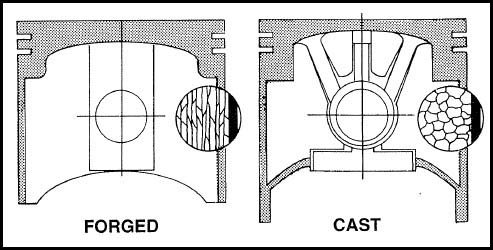

The difference between forged pistons and cast pistons in motorcycle parts

Motorcycle forged parts play a vital role in engine reliability and performance. Forged pistons stand out for their ability to handle high stress and heat.

The forging process changes the grain flow of metal, which increases strength and reduces weak spots.

These pistons can survive high RPM, forced induction, and extreme pressure.

Cast pistons cost less and work well in standard commuter bikes. They suit engines with moderate power and lower heat exposure.

Forged Pistons in Motorcycle Forged Parts

Forging Process

The forging process shapes motorcycle forged parts to achieve high performance and reliability. OEM motorcycle parts manufacturer begin by selecting the right material, such as 4032 aluminum alloy, known for its balance of strength and wear resistance. The process follows these steps:

Material Selection: Engineers choose alloys like 4032 for their properties.

Heating and Forging: The alloy heats up and then forms in a die under high pressure.

Trimming and Finishing: Workers trim the forged piston and heat-treat it to boost durability.

Coating: Technicians apply coatings to reduce friction and improve performance.

Quality Control: Inspectors check each piston to ensure it meets strict standards.

Machining of Ring Grooves: Machines cut grooves for piston rings, ensuring a precise fit.

Assembly: The piston receives its rings and fits into the engine.

This forging process changes the metal’s grain structure. It aligns the grains, making the motorcycle forged parts stronger and less likely to fail under stress. The process also removes internal defects, which improves the overall quality of forged pistons.

Strength and Durability

Forged pistons stand out for their strength and durability. The forging process causes several metallurgical changes that boost performance. The table below shows how these changes affect the piston:

Metallurgical Change | Effect on Piston Strength |

|---|---|

Strain Hardening | Increases strength and ductility |

Grain Refinement | Enhances fatigue endurance and impact toughness |

Healing of Porosity | Reduces defects, improving overall material integrity |

Forged pistons have higher tensile strength and longer fatigue life than cast pistons. This makes them ideal for motorcycle forged parts that face high stress and heat. For example, ProX pistons use 4032 aluminum alloy, which resists wear and maintains hardness at high temperatures. JE Pistons’ Pro Series line, used by professional race teams, demonstrates the durability and reliability of forged pistons in demanding conditions.

Motorcycle forged parts made with forged pistons last longer and handle stress better. Riders and engineers choose these pistons for high-performance motorcycles where strength and durability matter most.

Cast Pistons Overview

Casting Process

The casting process shapes pistons by pouring molten aluminum into a mold. This method allows manufacturers to produce complex shapes at a lower cost. Many oem cast pistons use this process because it supports high-volume production and keeps prices affordable. After the aluminum cools, workers remove the piston from the mold and perform finishing steps like machining and surface treatment.

However, the casting process can introduce certain defects. These defects may affect the performance and reliability of cast pistons. The table below lists common defects and their impact:

Defect Type | Impact on Performance |

|---|---|

Pores | Reduces mechanical properties, affecting reliability and service life. |

Inclusions | Can lead to quality issues and reduced performance due to material inconsistencies. |

Surface Defects | May cause aesthetic issues and affect the functionality of the part. |

Dimensional Inaccuracies | Can lead to poor assembly and failure to meet design requirements. |

Shrinkage Defects | Alters part performance due to uneven cooling and residual stresses. |

Note: These defects can result in reduced mechanical properties, increased production costs, and overall product quality issues.

Despite these risks, oem cast pistons remain popular for standard motorcycles. Manufacturers use strict quality control to minimize defects and ensure each piston meets design requirements.

Weight and Efficiency

Cast pistons offer a lighter alternative to forged pistons. The casting process creates a random grain structure, which results in a lighter piston but also makes it less strong. In typical motorcycle applications, forged pistons weigh more because the forging process aligns the grain structure for added strength. Cast pistons, on the other hand, help reduce the overall weight of the engine.

A lighter piston improves engine efficiency. It allows the engine to rev more freely and can enhance fuel economy. Many commuter motorcycles use cast pistons for this reason. The reduced weight also lowers the stress on connecting rods and crankshafts, which can extend the life of other engine parts.

Cast pistons provide a balance between cost, weight, and efficiency. They suit motorcycles that do not require extreme strength or high performance. Riders who value affordability and everyday reliability often choose cast pistons for their engines.

Pistons Performance Comparison

Mechanical Properties

Forged pistons and cast pistons show clear differences in mechanical properties. The forging process compresses the grain structure, which increases both yield strength and ductility. This build method results in pistons that can handle higher loads and resist cracking under stress. Cast pistons, produced by pouring molten metal into molds, have a random grain structure. This makes them more brittle and prone to failure when exposed to extreme power levels.

Type of Piston | Yield Strength | Ductility |

|---|---|---|

Forged | More ductile due to compressed grain structure | |

Cast | Weaker due to random grain structure | More brittle and prone to failure under stress |

Forged pistons are up to 30% stronger than cast pistons. The forging process creates a denser and more ductile material. Cast pistons, while lighter, cannot match the strength or toughness of forged pistons. This difference becomes critical in high-compression builds and engines designed for serious performance.

A second comparison highlights the results of standardized mechanical property tests:

Property | Forged Pistons | Cast Pistons |

|---|---|---|

Hardness | Typically lower due to rough cast microstructures | |

Tensile Strength | Superior due to uniform density and structure | Weaker due to internal defects and roughness |

Fatigue Strength | Better performance due to reduced internal flaws | Limited by casting defects and roughness |

Forged pistons deliver better fatigue strength and hardness, which means they last longer in engines that operate at high RPM or under heavy loads. Cast pistons, while suitable for standard engine parts, may not withstand the demands of extreme power levels.

Heat Resistance

Heat resistance plays a major role in piston performance and durability. Forged pistons excel in high-temperature environments. Their dense grain structure and ability to accept thermal barrier coatings help them survive in engines with high boost or compression ratios. Cast pistons, on the other hand, work best in engines with lower temperatures and moderate power.

Type | Maximum Operating Temperature Suitability |

|---|---|

Cast | Suitable for low temperatures (sub 11:1 compression ratios, N/A engines) |

Forged |

Thermal barrier coatings further enhance the heat resistance of pistons. These coatings reduce heat transfer and protect the piston from thermal fatigue. For example, the use of Y2O3 zirconia coatings can lower piston temperature by up to 16%, which improves durability in high performance engine builds. Trace elements added to aluminum-silicon alloys also boost fatigue resistance under high temperatures. Forged pistons benefit most from these technologies, making them the top choice for engines that demand serious performance and power.

Design Flexibility

The manufacturing process affects the design flexibility of both forged pistons and cast pistons. Cast pistons allow for more complex shapes and thinner walls because the molten metal fills intricate molds. This flexibility supports creative piston designs and lighter builds, which can improve efficiency in commuter motorcycles.

Forged pistons, while stronger, experience greater thermal expansion. This requires larger ring gaps and more clearance, which can lead to piston slap during cold starts. The piston may rock in the cylinder bore until it reaches operating temperature, causing increased wear. These factors can shorten the lifespan of forged pistons in some builds.

Cast pistons are easier to produce and support complex designs.

Forged pistons require precise machining and careful tolerance control.

The forging process results in a denser, more aligned grain structure, which enhances strength and durability.

Cast pistons, with their random grain structure, remain more brittle but allow for lighter and more efficient builds.

Cost Factors

Cost considerations often drive the choice between forged pistons and cast pistons. The forging process uses specialized equipment and requires more labor, which increases the cost. Cast pistons, produced in high volumes with simple molds, offer a more affordable solution for most standard engines.

Feature | Forged Pistons | Cast Pistons |

|---|---|---|

Production Process | Heated and formed under extreme pressure | Molten aluminum poured into molds |

Cost | Lower, more cost-effective | |

Strength | Stronger, more durable | Weaker, lighter |

Ideal Use | High horsepower engines (450+ HP) | Complex designs, smaller runs |

Material Structure | Aligned grain structure | Random grain structure |

Forged pistons justify their higher cost in builds that require extreme power levels, high-compression builds, or racing applications. Cast pistons remain the best choice for daily riders who value affordability and efficiency. Procurement managers and engineers must weigh cost considerations against the required performance, durability, and tolerance for each engine application.

Tip: Always match the piston type to the engine’s intended use. High performance engine builds benefit from forged pistons, while standard motorcycles achieve better value with cast pistons.

Choosing the Right Pistons for Your Motorcycle

High-Performance and Racing

Selecting pistons for high-performance motorcycles requires careful attention to detail. Wiseco forged pistons stand out in this category due to their superior strength and reliability. Engineers often look for pistons that can handle extreme conditions, such as high compression ratios and forced induction. Wiseco forged pistons deliver greater precision and tighter tolerances, which allow them to withstand the intense demands of racing. These pistons also reduce rotational weight and friction, leading to improved engine efficiency and less heat buildup.

When choosing between forged and cast pistons for a racing engine build, several factors come into play:

Bore size and compression ratio must match the engine’s specifications.

Material and coatings should offer maximum durability.

The piston must fit the specific engine model.

The intended application, such as track racing or off-road, determines the best piston choice.

Wiseco forged pistons can handle compression ratios as high as 14.5:1, far exceeding the limits of standard cast pistons. Their dense structure makes them smaller and lighter, which benefits both acceleration and reliability. For procurement managers, these pistons offer a dependable solution for severe duty applications.

Tip: High-performance motorcycles benefit from pistons that resist cracking and wear, especially under high RPM and extreme loads.

Daily Use and Commuting

For daily commuting, cast pistons often provide the best balance of cost and performance. Wiseco forged pistons may offer unmatched durability, but most commuter motorcycles do not require such high levels of strength. Cast pistons are lighter, which helps engines rev quickly and improves fuel efficiency.

The following table highlights key considerations for cast pistons in commuter motorcycles:

Property | Importance |

|---|---|

Strength | Withstands normal forces without breaking |

Wear Resistance | Maintains performance over time |

Heat Resistance | Handles typical engine temperatures |

Fatigue Strength | Prevents cracks from daily use |

Thermal Conductivity | Dissipates heat efficiently |

Lightweight | Improves fuel economy and engine response |

Machinability | Allows for cost-effective production |

Procurement managers often choose cast pistons for bulk production because they are cost-effective and suitable for entry-level motorcycles. However, they should consider engine condition and application needs. Wiseco forged pistons remain the top choice for riders who demand the highest reliability, even in daily use.

Note: Regular maintenance, such as ring changes, can extend piston life. Forged pistons generally last longer, but cast pistons are sufficient for most street motorcycles.

Forged pistons deliver superior strength and durability because their directional grain flow reduces structural defects. Cast pistons cost less but may crack under stress. Recent trends favor forged pistons for high-performance motorcycles due to their lighter weight and better heat resistance.

Forged pistons suit racing and competitive applications, while cast pistons work well for standard use.

Buyers should match piston choice to operational requirements, budget, and engine performance needs.

Experts recommend consulting technical specialists or manufacturers for tailored advice and selecting piston designs that fit specific riding conditions.

FAQ

What makes forged pistons stronger than cast pistons?

Forged pistons have a compressed grain structure. This structure increases strength and reduces weak spots. Cast pistons have a random grain structure, which makes them more brittle.

Are forged pistons always better for motorcycles?

Not always. Forged pistons work best in high-performance or racing engines. Cast pistons suit standard motorcycles that need cost-effective and lightweight parts.

Do forged pistons last longer than cast pistons?

Forged pistons usually last longer under high stress and heat. Cast pistons may wear out faster in extreme conditions, but they perform well in daily commuting.

Can cast pistons handle high temperatures?

Cast pistons can handle normal engine temperatures. High-performance engines generate more heat, so forged pistons resist thermal damage better.

How do I choose between forged and cast pistons?

Consider engine type and usage.

High power or racing: Choose forged pistons.

Daily riding or commuting: Cast pistons offer good value and efficiency.