Advantages and Disadvantages of Aluminum Hot Forging in 2025

Aluminum hot forging stands out as a metalworking process that shapes aluminum at high temperatures to produce lightweight, high-strength, and fatigue-resistant parts. This technique supports industries such as automotive and aerospace, where engineers must meet strict regulatory and sustainability goals. Recent advancements—like AI-driven simulations, automation, and real-time monitoring—make aluminum hot forging essential for manufacturing complex, high-performance components while reducing material waste and energy use.

Aluminum Hot Forging Overview

Process Basics

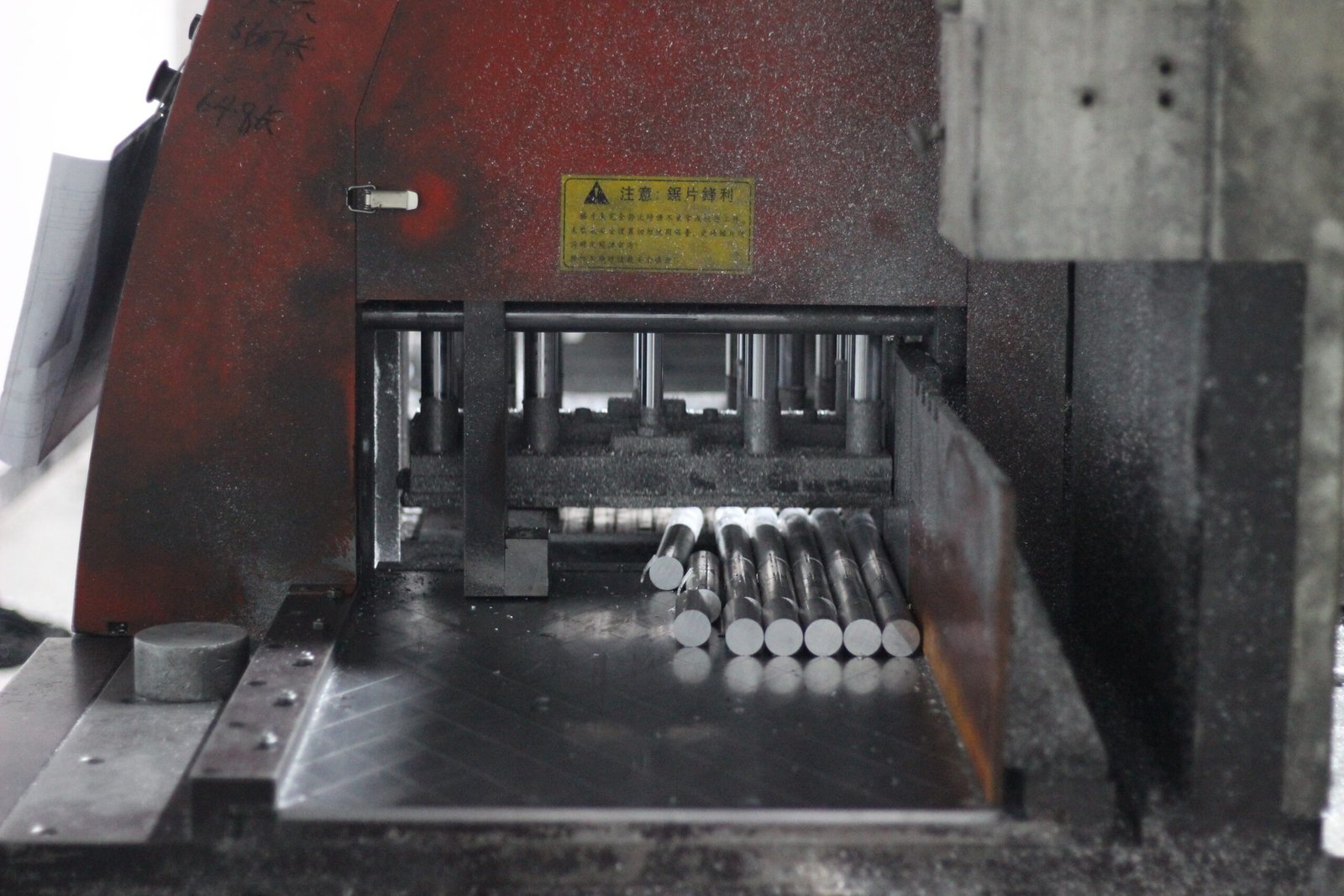

Aluminum hot forging is a metalworking process that shapes aluminum alloys at elevated temperatures. The process begins with selecting the right alloy based on the desired mechanical and physical properties. Operators then heat the aluminum billet to a temperature between 360°C and 520°C, making it malleable for forging. The heated billet undergoes deformation under high pressure using precision dies, which aligns the grain flow and enhances the final product’s strength. After shaping, trimming removes excess material, ensuring the part meets dimensional requirements. Heat treatment follows, optimizing mechanical properties such as strength and toughness while relieving residual stresses. The final step involves finishing operations like machining or grinding to achieve tight tolerances and a high-quality surface.

Process Step | Description | Influence on Product Properties |

|---|---|---|

Material Selection | Choosing the appropriate aluminum alloy based on required mechanical and physical properties. | Determines baseline strength, corrosion resistance, and machinability. |

Heating | Heating the aluminum billet to 360°C-520°C to make it malleable for forging. | Ensures proper grain structure and ductility for deformation. |

Schmieden | Shaping the heated billet under high pressure using dies, aligning grain flow. | Enhances strength, toughness, and refines grain structure. |

Trimming | Removing excess material (flash) to achieve precise shape. | Improves dimensional accuracy and surface finish. |

Heat Treatment | Processes like solution heat treating, aging, or annealing to optimize mechanical properties. | Increases strength, toughness, and relieves residual stresses. |

Finishing | Machining operations such as milling, drilling, or grinding to meet final dimensions and finish. | Achieves tight tolerances and desired surface quality. |

Process parameters such as temperature and strain rate play a critical role. Proper control prevents defects like underfilling, folding, or cracks, which can compromise mechanical performance. Advanced simulation tools help optimize these parameters, reducing the risk of defects and improving consistency.

Material Properties

Hot forging significantly influences the properties of aluminum alloys. The process improves ductility by refining grain size, which enhances tensile elongation. Grain size control remains essential; insufficient deformation or forging below the recrystallization temperature can cause abnormal grain growth, leading to surface roughness and reduced ductility. Regions subjected to greater deformation during forging exhibit better grain size control and fewer defects. While strength properties remain relatively stable, ductility and toughness benefit most from optimized forging conditions. Integrated processes, such as combining solution treatment, forging, and aging, further enhance mechanical performance and reduce processing time.

Note: Forging temperature and the amount of deformation directly affect the microstructure and mechanical behavior of the final product. Operators must monitor these factors closely to ensure consistent quality.

Application Areas

Aluminum hot forging supports a wide range of industries due to its ability to produce lightweight, high-strength components. The automotive and aerospace sectors lead in adopting this technology, driven by the need for lightweight parts that improve fuel efficiency and meet emission standards. Electric vehicle manufacturers increasingly rely on aluminum forgings for their favorable strength-to-weight ratio and thermal conductivity. The defense industry uses forged aluminum for missile and aircraft components, while industrial machinery, oil and gas, and construction equipment also benefit from the process.

Aspect | Details |

|---|---|

Market Size (North America) | USD 3.18 billion in 2018; projected USD 4.18 billion by 2030 |

Key Application Areas | Aerospace (engine parts, landing gear, structural elements), Defense (missile, aircraft parts) |

Market Drivers | Lightweight component demand, government investments, emission regulations, EV growth |

Regional Strength | North America leads in aerospace and defense applications |

Example Data | U.S. aerospace exports worth USD 89 billion in 2021; U.S. accounts for ~40% global defense spending |

Luft-und Raumfahrt

Industrial Machinery

Oil and Gas

Construction Equipment

Consumer Goods

The growing focus on sustainability and the adoption of advanced technologies such as AI and IoT further expand the application of aluminum hot forging across these sectors.

Advantages of Aluminum Hot Forging

Design Flexibility

Complex Shapes

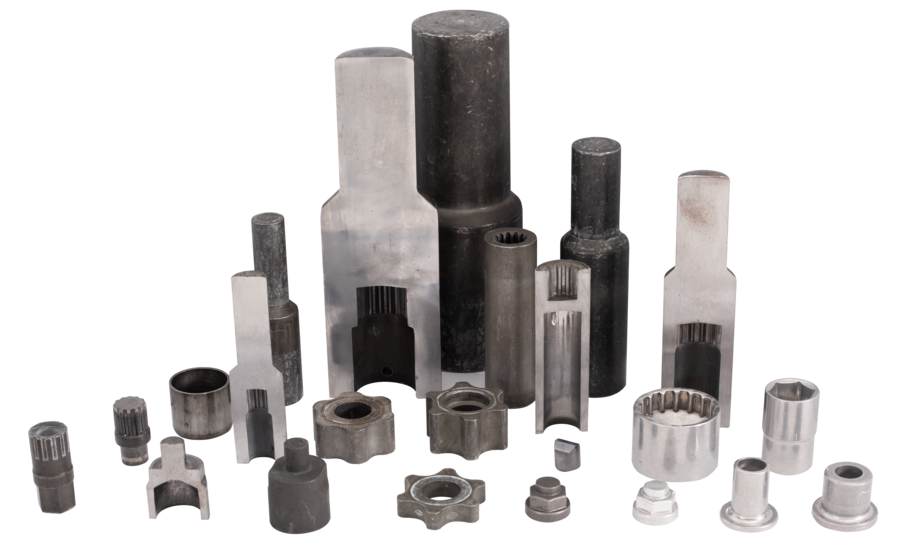

Hot forging enables manufacturers to create parts with complex geometries that are difficult or impossible to achieve with cold forming or machining. The elevated temperatures used in hot forging increase the deformability of aluminum alloys, allowing the metal to flow into intricate die cavities. This process supports the production of large, customized components with excellent surface finishes.

Cold forging typically produces simple shapes such as rods, strips, and foils.

Hot forging excels at forming parts with intricate features and tight tolerances, including gears, crankshafts, and specialized profiles.

The process uses high-strength tool steel dies, which provide precise shaping and repeatability.

Aluminum hot forging allows for the easy manipulation and cutting of aluminum into ornate or highly detailed shapes. This flexibility makes it a preferred choice for industries that demand both performance and design complexity.

Intricate Parts

Hot forging supports the fabrication of intricate parts by combining high temperature and compressive forces. Drop hammers, hydraulic presses, and mechanical presses apply these forces, facilitating plastic deformation and dynamic recrystallization. Aluminum alloys such as 6061 and 7075 respond well to this process, enabling the creation of detailed and high-strength components.

Note: The ability to produce intricate and large parts with minimal post-processing distinguishes hot forging from other metal forming methods.

Mechanical Properties

Strength

Hot forging significantly enhances the mechanical properties of aluminum alloys, particularly strength. The process aligns the grain flow with the shape of the part, which increases resistance to fatigue and mechanical stress. For example, hot forging of 7075 aluminum alloy followed by infrared heat treatment improves tensile strength, hardness, and Young’s modulus. Finer and denser precipitations formed during this process contribute to age hardening and higher strength.

Manufacturers often select hot forging when they require parts that must withstand high loads or repeated stress cycles. The resulting components demonstrate mechanical properties comparable to steel but with a superior strength-to-weight ratio.

Ductility

Ductility, or the ability of a material to deform without breaking, also benefits from hot forging. The process refines grain size and promotes uniform microstructure, which enhances tensile elongation. While certain post-forging treatments, such as cryogenic rolling, can increase strength at the expense of ductility, hot forging combined with optimized heat treatment maintains or moderately improves ductility compared to other methods.

Tip: Maintaining a balance between strength and ductility is crucial for applications in automotive and aerospace sectors, where both properties are essential for safety and performance.

Structural Integrity

Grain Structure

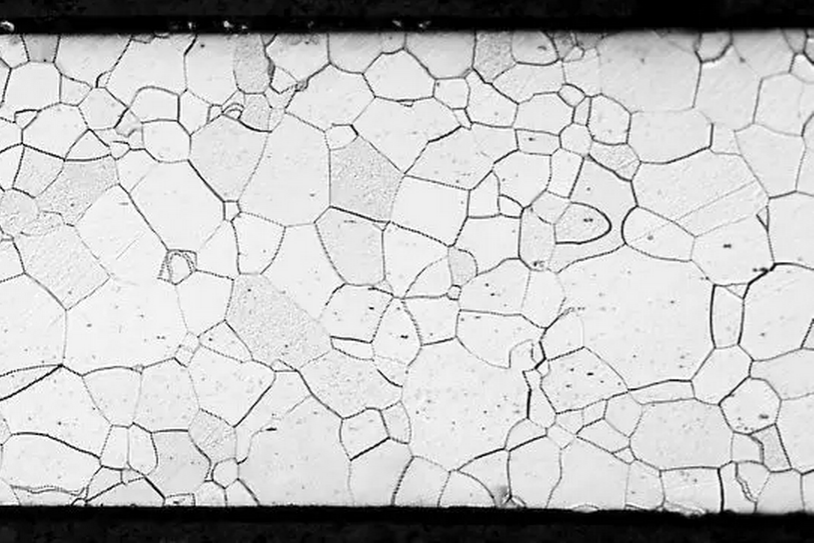

Forging at elevated temperatures transforms the internal structure of aluminum alloys. The process eliminates coarse dendrites and internal defects, promoting grain refinement and microstructural homogeneity. Successive forging and heat treatment cycles produce uniform grain structures with constrained grain size, preventing abnormal grain growth.

Case studies show that multidirectional forging converts coarse dendritic structures into refined, homogeneous grains. This transformation significantly enhances both the microstructural characteristics and the mechanical properties of the final product.

Reduced Porosity

Hot forging reduces porosity within aluminum components, which directly improves structural integrity. Experimental data from hot forging arc-based additive manufacturing demonstrates a 22% reduction in porosity after forging. Grain size refinement accompanies this reduction, with notable decreases in both the top and middle regions of forged parts.

A decrease in porosity and an increase in grain uniformity correspond with higher ultimate tensile strength and improved reliability. These advantages of hot forging make it a preferred process for critical applications where structural integrity cannot be compromised.

Structural Integrity Benefit | Description |

|---|---|

Grain Refinement | Eliminates coarse dendrites, produces uniform grain structure, and prevents abnormal growth. |

Reduced Porosity | Lowers internal voids, increases tensile strength, and enhances reliability. |

Cost Efficiency

Fewer Secondary Operations

Hot forging of aluminum delivers significant cost savings by minimizing the need for secondary operations. The process maintains elevated temperatures, which allows the material to flow smoothly and fill die cavities completely. This results in uniform, high-quality parts with improved mechanical properties and surface finishes. Manufacturers benefit from:

Reduced need for additional machining or finishing due to precise dimensional accuracy.

Fewer post-forging treatments, as the process already enhances surface quality and mechanical strength.

Lower material waste, since the process produces near-net-shape components.

Drop forging, a common form of hot forging, stands out for its ability to produce complex shapes efficiently. Although initial tooling costs can be high, these expenses are offset by efficiency gains and lower per-unit costs in large production runs. Industries that require lightweight, high-strength parts—such as automotive and aerospace—prefer hot forging for its ability to deliver cost-effective, high-volume manufacturing.

High-Volume Production

Hot forging supports high-volume production by ensuring repeatability and consistency. The process guarantees tight tolerances and uniformity across large batches, which is essential for mass manufacturing. Key advantages include:

High-speed production cycles, reducing overall lead times.

Consistent part quality, which lowers the risk of defects and rework.

Economies of scale, as the cost per unit decreases with larger production volumes.

The lightweight nature and superior strength-to-weight ratio of hot-forged aluminum make it a popular choice for industries focused on cost-effective, large-scale output.

Surface Finish

Dimensional Accuracy

Precision aluminum hot forging achieves tight dimensional tolerances and excellent surface finish directly from the die. The compressive forces during forging smooth the surface and ensure complete filling of the die cavity. This process avoids the thermal distortion often seen in casting, further improving dimensional accuracy. The table below summarizes the quality aspects:

Quality Aspect | Description |

|---|---|

Surface Finish | Generally good; may require additional treatment for higher standards |

Dimensional Accuracy | High, capable of achieving consistent and precise dimensions |

Forging produces parts with stable dimensions, which reduces the need for further adjustments or corrections during assembly.

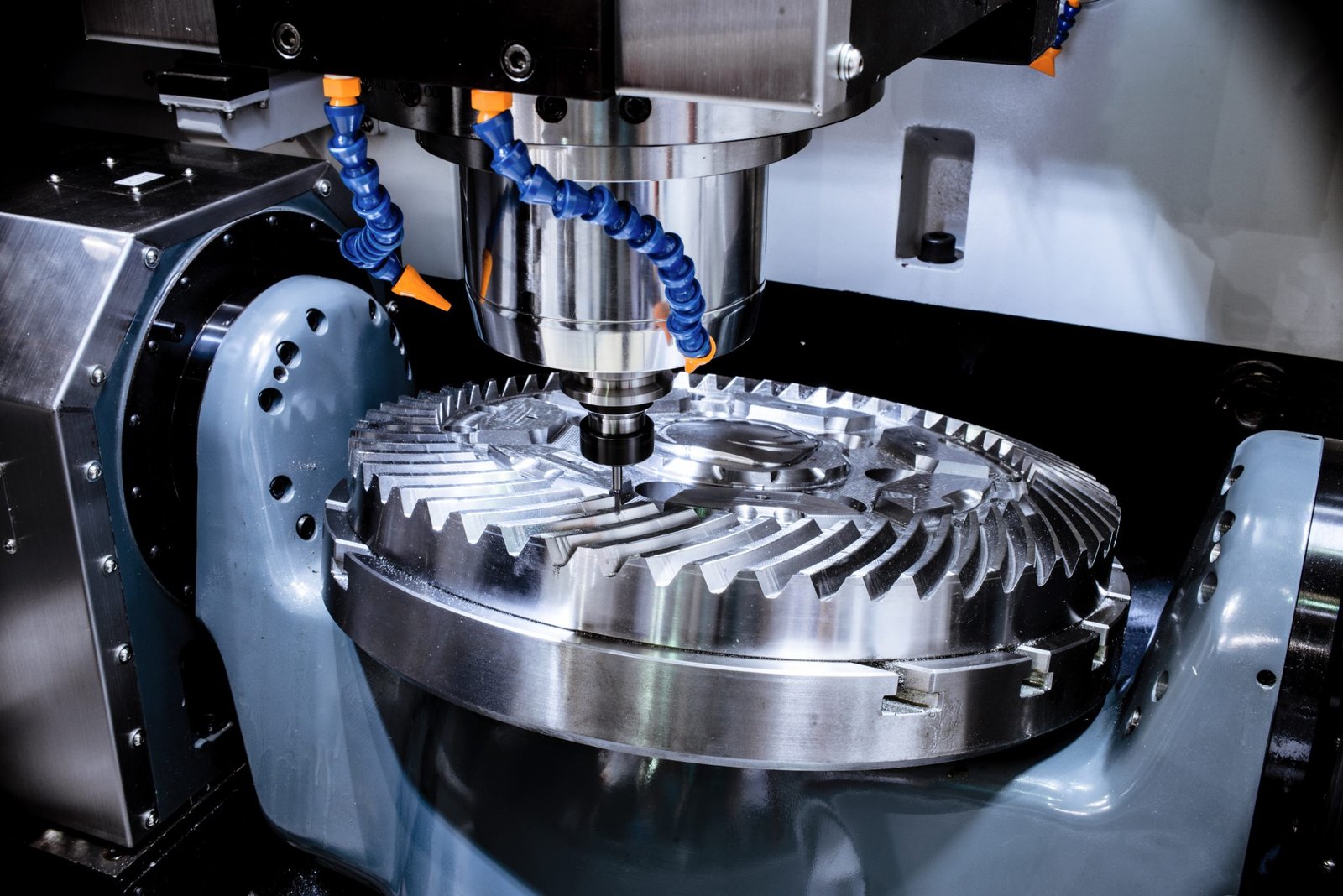

Reduced Machining

Hot forging increases the malleability of aluminum, making it easier to shape complex products with less machining. Elevated temperatures reduce strain hardening, which simplifies subsequent machining steps. The process also refines the grain structure, enhancing strength and durability. As a result, manufacturers spend less time and resources on machining to achieve desired mechanical properties. Removing unnecessary webbing before heat treatment further reduces post-quench distortion, leading to easier machining and improved part quality.

Tip: By reducing the need for extensive machining, hot forging not only saves time but also lowers production costs and improves overall efficiency.

Environmental Benefits

Material Waste Reduction

Recent studies highlight that hot forging and related plastic deformation recycling methods significantly reduce material waste. Direct recycling of aluminum chips through hot press forging eliminates the need for energy-intensive melting. This approach enables direct reuse of aluminum, minimizing waste generation and supporting sustainable manufacturing practices.

Energy Savings

Hot forging offers substantial energy savings compared to traditional melting and casting. Aluminum alloy melting accounts for a large portion of total energy use in aluminum processing. By avoiding or reducing reliance on melting, hot forging conserves energy and lowers the carbon footprint. Technologies such as waste heat recovery and efficient furnace design further enhance these savings. Life cycle assessments confirm that recycling aluminum through forming processes, including hot forging, delivers superior environmental outcomes and promotes circular economy principles.

Note: Hot forging not only improves production efficiency but also aligns with global sustainability goals by reducing both material waste and energy consumption.

Disadvantages of Hot Forging

Dimensional Tolerance

Thermal Expansion

Aluminum hot forging presents significant challenges in maintaining tight dimensional tolerances. When manufacturers heat aluminum alloys to high temperatures, the metal expands. As the part cools, it contracts, often unpredictably. This thermal expansion and contraction can lead to deviations from intended dimensions. Unlike cold forging, which produces parts with high dimensional precision and minimal shrinkage, hot forging often results in lower accuracy. Scale formation on the surface and microstructural changes during the process further degrade both dimensional accuracy and surface finish. These issues make it difficult to achieve the near-net shape and tight tolerances that some industries require.

Deformation Issues

Deformation problems arise frequently during hot forging. High strain rates and elevated temperatures cause thermomechanical instability in aluminum alloys. Most of the plastic work done during forging converts into heat, which leads to thermal softening. As a result, the material may experience flow softening and strain localization. These effects can trigger failure mechanisms such as void nucleation and growth. In bimetallic components, differences in thermal expansion between aluminum and other metals, like steel, can cause internal cracking and tearing. Temperature differentials and wall thickness play a role in the severity of these defects. Even after forging, cracks may continue to grow as the part cools. Manufacturers must carefully select core materials and control temperature gradients to minimize these risks.

Warping and Brittleness

Cooling Challenges

Warping and brittleness represent major risks during the cooling phase of aluminum hot forging. The cooling rate and method directly affect the hardness and ductility of the final product. If the metal cools too quickly or unevenly, it may develop internal stresses that cause warping or cracking. Aluminum’s high thermal expansion means it shrinks more than other metals during cooling, which can create gaps or separation in bimetal components. Improper cooling can also lead to the formation of brittle intermetallic phases at interfaces, especially in steel-aluminum combinations. These phases weaken the joint and increase the likelihood of crack initiation. Water cooling, if not properly managed, can introduce additional defects such as white spots or martensite-related issues.

Cooling below the recrystallization temperature causes strain hardening and the formation of microscopic crystals, making the metal brittle.

Uneven or rapid cooling can result in warping, cracks, or coarse grains.

Controlled cooling strategies, such as inhomogeneous heating or isothermal forging, help reduce these risks.

Structural Risks

Structural risks in hot forging stem from both process parameters and material properties. Improper heating or cooling can cause defects like cracks, inclusions, and coarse grains. In bimetallic parts, the mismatch in thermal expansion between aluminum and steel requires precise temperature management. If not controlled, this mismatch can lead to delamination, excessive thermal stresses, or the formation of thick intermetallic layers that degrade mechanical properties. Some defects, such as blue brittleness in steel, occur when temperatures drop below critical thresholds during cooling. Not all structural defects can be remedied by post-forging heat treatments, which means some parts may suffer from reduced mechanical performance or even fail during final tempering.

Tip: Post-forging heat treatments like tempering and annealing are essential to relieve stresses, improve ductility, and reduce brittleness. However, these steps add time and cost to the overall process.

Grain Structure Variations

Qualität Control

Grain structure plays a critical role in the quality and consistency of forged aluminum products. Hot forging typically produces a continuous and aligned grain flow, which enhances strength and fatigue resistance. However, variations in forging temperature and strain rate can lead to inconsistent grain size and distribution. Dynamic recrystallization, which occurs at higher temperatures and appropriate strain rates, refines the grain structure and improves mechanical properties. If process parameters are not optimized, the result may be coarse or uneven grains, reducing the reliability of the final product. Quality control measures must focus on maintaining uniform temperature and deformation rates to ensure consistent microstructure.

Attribute | Cast Aluminum | Forged Aluminum |

|---|---|---|

Grain Structure | Random and fragmented | Continuous and aligned grain flow |

Internal Defects | Higher porosity, cracks, inclusions | Very low porosity, dense and defect-free |

Strength | Moderate to low | High due to grain refinement |

Fatigue Resistance | Low, weakened by internal voids | Excellent, aligned grains handle stress cycles well |

Consistency | Lower due to defects | High consistency due to dense microstructure |

Atmospheric Reactions

Atmospheric reactions during hot forging can compromise both surface quality and internal integrity. Exposure to oxygen at high temperatures leads to oxidation, forming oxide scales that degrade the surface finish and dimensional accuracy. Moisture in the furnace atmosphere can cause hydrogen formation, resulting in blistering. Contaminants such as sulfur compounds further damage the protective oxide film on aluminum. To address these issues, manufacturers implement several quality control measures:

Thoroughly dry parts and racks before heating to minimize moisture.

Minimize furnace atmosphere moisture and design racks to prevent water entrapment.

Remove sulfur compounds from parts and furnace environments.

Use protective compounds in the furnace to react with moisture and reduce blistering.

Anodize parts before heat treatment to form a stable oxide film.

Regularly clean furnace equipment to remove oxide residues.

Apply protective coatings or use advanced heating technologies for uniform heating and reduced oxidation.

These steps help maintain product quality and reduce the risk of defects caused by atmospheric exposure during forging.

Machining Difficulty

Lack of Work Hardening

Forging aluminum at high temperatures changes its microstructure, but it does not provide the same work hardening benefits as cold working. During hot forging, the metal’s grains realign and recrystallize, which improves ductility but reduces the hardening effect that typically results from deformation at lower temperatures. As a result, forged aluminum parts may lack the increased surface hardness and wear resistance seen in cold-forged components. This limitation can affect the performance of parts that require high surface durability, especially in applications where friction and wear are concerns.

Post-Processing Needs

Machining forged aluminum parts presents several challenges that can impact production efficiency and quality. After hot forging, manufacturers often encounter:

Material sticking to cutting tools, which results from aluminum’s tendency to adhere at high temperatures.

Deep oxidation layers formed during forging, which complicate achieving a smooth surface finish.

Accelerated tool wear due to the abrasive nature of aluminum alloys.

These issues make it difficult to achieve precise dimensional tolerances and desired surface finishes. Production teams may need to use advanced machining techniques, specialized tool coatings, or frequent tool changes to maintain quality. The need for additional post-processing steps, such as grinding or polishing, increases both time and cost. Precise temperature control during forging is essential to minimize defects that complicate machining. Companies often invest in computer simulations and automation to optimize material selection, temperature management, and die design, but these solutions add complexity to the overall process.

Note: Machining difficulties after forging can lead to increased downtime, higher operational costs, and reduced throughput, especially in high-volume production environments.

Cost and Complexity

Tooling Investment

The initial investment in tooling for aluminum forging is significantly higher than for casting or machining. Closed-die forging requires high-precision tool steel dies, which must withstand repeated exposure to high temperatures and pressures. The cost of simple dies ranges from $2,000 to $10,000, while complex multi-part dies can exceed $100,000. Although these upfront costs are substantial, they are often justified by long-term savings. Forging produces near-net-shape parts, which reduces the need for extensive machining and lowers material waste. For high-volume production, the cost per unit decreases as tooling expenses are spread across many parts.

Tooling Type | Cost Range (USD) |

|---|---|

Simple Dies | $2,000 – $10,000 |

Complex Multi-part Dies | $20,000 – $100,000+ |

However, the high cost of tooling remains a barrier for small production runs or custom components. Companies must carefully evaluate production volume and part complexity before committing to forging as their manufacturing method.

Heat Treatment

Heat treatment is a critical step after forging aluminum parts. This process adjusts the hardness, strength, and ductility of the final product. Heat treatment costs are moderate to high, especially when compared to cold forging or casting. The process requires substantial energy for heating, which increases operational expenses. Batch heating in large production runs can improve cost efficiency by reducing fuel consumption per unit, but smaller batches do not benefit as much from these savings.

The complexity of the forging process also affects scalability and lead times. Forging aluminum requires precise control of temperature and pressure, which adds to the time and expertise needed for each production cycle. Production speed for a single forged part can range from one to several hours, depending on size and complexity. As complexity increases, lead times grow longer, and scalability becomes more challenging.

Tip: Companies should weigh the disadvantages of hot forging, such as high tooling and heat treatment costs, against the benefits of improved material properties and long-term savings in high-volume production.

Aluminum Hot Forging vs. Other Methods

Cold Forging

Cold forging shapes aluminum alloys at or near room temperature. This process increases strength and hardness through strain hardening, which improves fatigue and fracture resistance. Manufacturers value cold forging for its high dimensional accuracy and excellent surface finish. The process also reduces material scrap, making it efficient for high-volume production of simple shapes such as fasteners and gears.

However, cold forging requires materials with high ductility. It demands precise tooling, which increases initial costs. The process struggles with forming complex geometries. Hot forging, in contrast, operates at elevated temperatures. This allows for greater material plasticity, enabling the creation of intricate shapes and improved internal structure. Hot forging enhances ductility and toughness but sacrifices some dimensional accuracy and consumes more energy due to heating requirements.

Selection between cold and hot forging depends on part complexity, production volume, and desired mechanical properties. Cold forging suits high-volume, precision parts, while hot forging excels with complex shapes and improved toughness.

Key Differences:

Cold forging: High precision, better surface finish, lower energy costs, limited to simple shapes.

Hot forging: Greater design flexibility, improved toughness, higher energy consumption, lower dimensional accuracy.

Casting

Casting involves pouring molten aluminum into a mold to achieve the desired shape. This method offers exceptional design flexibility, allowing for complex geometries, thin walls, and integrated features. High-pressure die casting (HPDC) delivers fast cycle times, making it ideal for mass production. Sand and gravity casting methods suit lower volumes but require more finishing.

A comparison highlights the main differences:

Aspect | Aluminum Hot Forging | Aluminum Casting |

|---|---|---|

Superior mechanical properties, refined grain structure, porosity-free, better surface finish, tighter tolerances | Complex shapes, variable surface finish, potential for porosity and shrinkage defects | |

Production Speed | Longer cycles, 5-7 week lead times, best for medium to high volumes | HPDC: very fast cycles; sand/gravity: slower, flexible for various volumes |

Cost | Higher tooling costs, better material utilization, reduced secondary operations | Tooling cost varies, higher scrap rates, more post-processing, economical for complex/low volume |

Forged parts deliver higher strength-to-weight ratios and reliability, especially in stressed applications. Casting remains the preferred choice for intricate designs and lower production volumes, despite the risk of internal defects and additional finishing needs.

Additive Manufacturing

Additive manufacturing (AM) builds aluminum parts layer by layer, enabling unprecedented geometric freedom. This process eliminates the need for tooling, allowing rapid design changes and the creation of complex, lightweight structures such as lattices. AM suits low-volume or highly customized production.

A direct comparison reveals important distinctions:

Aspect | Aluminum Hot Forging | Additive Manufacturing (AM) |

|---|---|---|

Limited by die shape, high tooling costs, less flexible for design changes | Enables complex, customized shapes, rapid iteration, no tooling required | |

Material Properties | Superior due to solid-state deformation, fine-grained microstructure, high fatigue resistance | Properties vary, potential for porosity, evolving standards, some methods improve microstructure |

Environmental Impact | High recyclability, resource-intensive tooling, reduced need for further processing | Reduces material waste, but powder production is energy intensive, best for low volume or complex, performance-driven parts |

AM reduces material waste by up to 80% in final parts, but powder production consumes significant energy. Hot forging remains the standard for applications demanding ultimate mechanical properties and high reliability.

Process Selection

Selecting the right manufacturing process for aluminum components in 2025 requires a careful evaluation of multiple factors. Each method—hot forging, cold forging, casting, and additive manufacturing—offers unique strengths and limitations. Decision-makers must align process capabilities with the specific needs of their application.

Key considerations for process selection include:

Application requirements: Engineers must assess load-bearing capacity, operating environment, and functional demands. For example, aerospace and automotive parts often require high strength and fatigue resistance.

Material selection: Choosing the appropriate aluminum alloy, such as 6061 or 7075, ensures the part meets strength, corrosion resistance, and machinability targets.

Process type: The complexity of the part, production volume, and budget influence whether open-die, closed-die, or ring rolling is most suitable.

Design optimization: Features like draft angles and fillet radii can simplify manufacturing and reduce the need for secondary machining.

Tolerance and dimensional accuracy: Defining precise tolerances is essential for parts that must fit or function within tight assembly constraints.

Surface finish and coatings: Selecting treatments such as anodizing or plating can improve corrosion and wear resistance, extending part lifespan.

Quality assurance: Implementing inspections and non-destructive testing helps maintain reliability and part integrity.

Supplier qualification: Working with experienced suppliers who hold relevant certifications ensures consistent quality and process control.

Cost analysis: A thorough review of total costs—including tooling, production, material waste, and lifecycle expenses—supports economic decision-making.

Process control also plays a vital role in achieving optimal results. The following steps help ensure high-quality outcomes:

Control pre-forging heating. Proper temperature management increases aluminum plasticity, reduces forming force, and prevents overheating.

Apply effective lubrication during deformation. Good lubrication minimizes friction, improves metal flow, and extends die life.

Select robust mold materials. Dies must withstand high temperatures and stress to avoid premature failure and economic loss.

Tip: Companies should match process selection to both technical requirements and business goals. A well-chosen method delivers reliable performance, cost efficiency, and long-term value.

Engineers who systematically evaluate these factors can confidently select the most appropriate process for their aluminum parts, ensuring both performance and profitability in 2025.

Decision Factors for 2025

Application Needs

Engineers and manufacturers must first evaluate the specific requirements of their projects. Aluminum hot forging suits applications that demand high strength, lightweight construction, and complex geometries. Aerospace and automotive sectors often select this process for critical structural parts. Electric vehicle producers favor hot forging for battery housings and suspension components due to the superior strength-to-weight ratio.

Key application considerations include:

Load-bearing capacity: Hot-forged aluminum parts handle repeated stress and fatigue better than cast or cold-formed alternatives.

Precision and complexity: Projects that require intricate shapes or tight tolerances benefit from the flexibility of hot forging.

Operating environment: Components exposed to extreme temperatures or corrosive conditions perform well when forged from high-grade aluminum alloys.

Tip: Teams should match the forging process to the end-use environment and performance expectations. This approach ensures reliability and safety.

Cost Analysis

Cost remains a decisive factor in process selection. Aluminum hot forging involves significant upfront investment in tooling and equipment. However, high-volume production can offset these initial expenses. Companies must analyze both direct and indirect costs to determine overall value.

Cost Factor | Hot Forging Impact | Notes |

|---|---|---|

Tooling | High initial cost | Spreads over large production runs |

Energy consumption | Moderate to high | Efficient with modern furnaces |

Material utilization | High efficiency | Less waste than casting |

Secondary operations | Reduced need | Lowers total production cost |

Maintenance | Regular die upkeep required | Extends tool life |

Manufacturers should calculate the break-even point for each project. For small batches or prototypes, alternative methods like casting or additive manufacturing may offer better economics. For mass production, hot forging delivers long-term savings through reduced waste and fewer post-processing steps.

Industry Trends

Industry trends in 2025 shape the adoption of aluminum hot forging. Sustainability drives many decisions. Companies seek processes that minimize energy use and material waste. Hot forging aligns with these goals, especially when paired with direct recycling and waste heat recovery.

Automation and digitalization also influence process selection. Smart forging lines use sensors and AI to monitor temperature, pressure, and material flow. These technologies improve consistency and reduce human error. Manufacturers who invest in digital twins and real-time analytics gain a competitive edge.

The shift toward electric vehicles and lightweight transportation increases demand for forged aluminum parts. Regulatory pressure for lower emissions and higher fuel efficiency accelerates this trend. Aerospace, defense, and renewable energy sectors also expand their use of forged aluminum due to its performance advantages.

Note: Companies that monitor industry trends and invest in advanced forging technologies position themselves for growth and resilience in a changing market.

Aluminum hot forging delivers strong, ductile parts with complex shapes, but it brings challenges like higher tooling costs and lower dimensional accuracy. Manufacturers should consider this process for medium to large components that require enhanced mechanical properties and near-net shape forming. The table below highlights key recommendations:

Aspect | Practical Recommendation for Manufacturers |

|---|---|

Improved Ductility & Formability | Use hot forging for larger, complex parts that require intricate shapes and better material flow. |

Enhanced Mechanical Properties | Plan for post-forging heat treatments to optimize strength and fatigue resistance. |

Lower Dimensional Accuracy & Surface Finish | Prepare for additional machining and finishing to address rougher surfaces and less precise tolerances. |

Tooling Costs | Budget for high initial die costs and potential shorter tool life. |

For optimal results, manufacturers should consult with forging specialists or pursue further research to match process capabilities with project needs.

FAQ

What is the main benefit of aluminum hot forging over casting?

Aluminum hot forging produces parts with higher strength and better fatigue resistance than casting. The process aligns the grain structure, which improves mechanical properties. Manufacturers often choose hot forging for critical components that require reliability and durability.

Can aluminum hot forging achieve tight dimensional tolerances?

Hot forging can achieve good dimensional accuracy, but not as tight as cold forging or machining. Thermal expansion and contraction during processing may cause slight deviations. Additional machining may be necessary for parts that require very precise tolerances.

Is aluminum hot forging environmentally friendly?

Yes. Hot forging reduces material waste and energy consumption compared to traditional melting and casting. Many manufacturers use direct recycling and waste heat recovery to further lower the environmental impact. This process supports sustainability goals in modern manufacturing.

Which industries use aluminum hot forging the most?

Luft-und Raumfahrt, automotive, and defense industries rely heavily on aluminum hot forging. These sectors demand lightweight, high-strength parts for safety and performance. Electric vehicle manufacturers also use forged aluminum for battery housings and structural components.

What are the main challenges in machining forged aluminum parts?

Machining forged aluminum can be difficult due to oxidation layers and material sticking to cutting tools. Tool wear increases, and achieving a smooth surface finish may require advanced techniques. Manufacturers often use specialized coatings and frequent tool changes to maintain quality.

How does hot forging affect the grain structure of aluminum?

Hot forging refines and aligns the grain structure of aluminum alloys. This process eliminates internal defects and reduces porosity. The result is a part with improved strength, ductility, and fatigue resistance compared to cast or cold-formed aluminum.

What factors influence the cost of aluminum hot forging?

Tooling investment, production volume, and heat treatment requirements drive the cost of aluminum hot forging. High initial die costs spread over large production runs. Efficient material use and reduced secondary operations can lower overall expenses for mass production.

Can hot forging be used for small production runs?

Hot forging is less cost-effective for small batches due to high tooling and setup costs. Manufacturers often select casting or additive manufacturing for prototypes or low-volume orders. Hot forging becomes economical when producing large quantities of the same part.