Applications of Aluminum Forging in Automotive and Aerospace

Aluminum forging industry experts recognize the vital role of aluminium forging in automotive and aerospace sectors. Engineers rely on aluminium forging to create high-performance, safety-critical components that demand precision and durability. The superior strength-to-weight ratio of aluminum forging enhances vehicle and aircraft efficiency. Recent market data shows that aluminum forging accounts for over 56% of revenue share in automotive components, reflecting its dominance in chassis and suspension assemblies. Precise manufacturing enables corrosion resistance and weight reduction, which remain essential for advanced designs. The aluminum forging industry continues to prioritize precision and reliability across all applications.

Segment

Aluminum Forging Market Revenue Share (2024)

Notes on Usage and Comparison to Other Materials

Automotive

Over 56%

Dominant use in chassis, suspension, and wheels.

Luft-und Raumfahrt

Significant but unspecified exact %

Major material for lightweight airframes.

Aluminum Forging Overview

What Is Aluminum Forging

Aluminium forging shapes metal using heat and pressure, refining its internal structure for superior performance. The forging process involves heating aluminum to temperatures between 350°C and 500°C, then pressing, hammering, or rolling it into the desired form. Open-die forging allows repeated impacts to shape the metal, while closed-die forging encloses the billet for complex, high-precision parts. Cold forging shapes aluminum at room temperature, producing intricate designs with minimal waste. Unlike casting, which can introduce defects and lower strength, aluminium forging produces components with uniform grain flow and fewer imperfections. The aluminum forging industry relies on these methods to deliver reliable, high strength parts for demanding applications.

Key Properties

Forged aluminium parts exhibit exceptional mechanical properties. The forging process enhances tensile strength, fatigue resistance, and hardness. For example, forged aluminum alloys with T6 heat treatment can achieve tensile strengths around 300 MPa, yield strengths near 260 MPa, and hardness values close to 92 Hb. The 6061-T6 alloy, commonly used in the aluminum forging industry, offers an ultimate tensile strength of about 310 MPa and a yield strength of 270 MPa. These values demonstrate the high strength and durability of aluminium forging. The refined grain structure also improves fatigue resistance, making forgings ideal for components exposed to repeated stress.

Why It Matters

Aluminium forging plays a critical role in automotive and aerospace sectors. The aluminum forging industry produces high strength, lightweight parts that improve fuel efficiency and performance. Forgings minimize internal voids and porosity, increasing reliability under extreme conditions. Aerospace-grade aluminium forging offers excellent corrosion resistance and fatigue resistance, ensuring safety and longevity in harsh environments. The forging process enables the production of complex shapes with tight precision, supporting the creation of safety-critical components. Automotive and aerospace manufacturers depend on aluminium forging for parts that must meet strict standards for strength, precision, and durability.

Applications of Aluminum Forging in Automotive

Suspension Parts

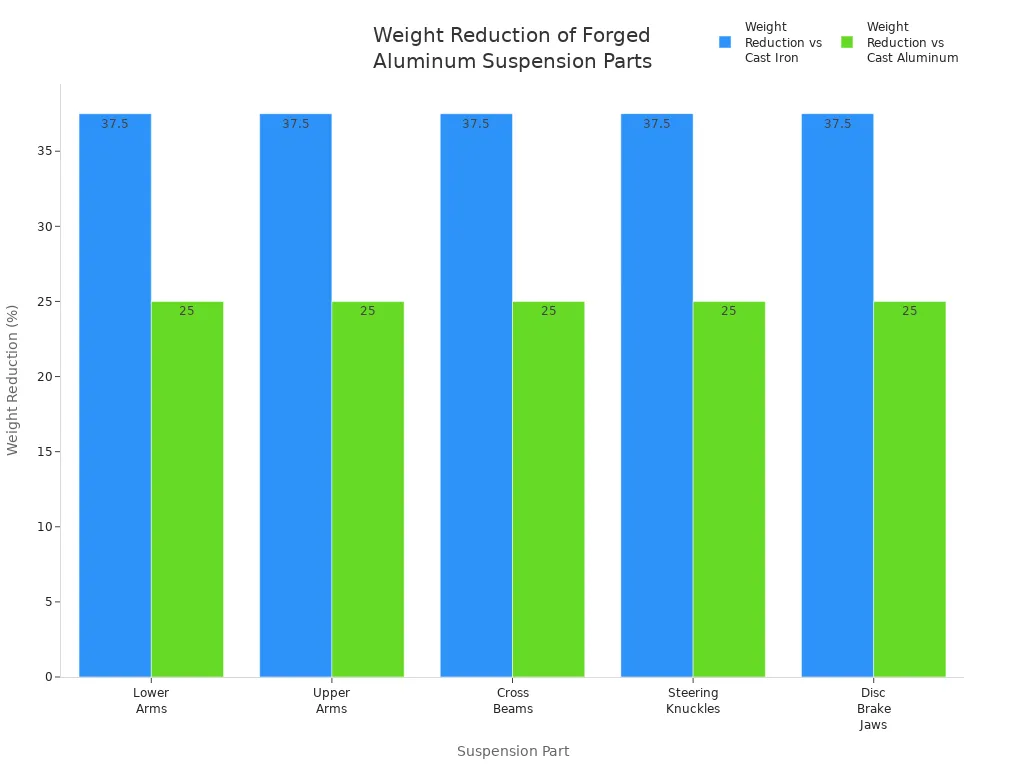

Automotive engineers rely on aluminium forging to produce suspension components that deliver high strength and reduced weight. Modern vehicles feature forged aluminium parts such as lower arms, upper arms, cross beams, steering knuckles, and disc brake jaws. These components, typically made from 6061 alloy, offer significant weight savings compared to cast iron and cast aluminum alternatives. The forging process refines the grain structure, resulting in high toughness and improved vibration reduction. This enhances vehicle handling and extends the lifespan of suspension systems.

Suspension Part | Aluminum Alloy | Weight Reduction Compared to Cast Iron | Weight Reduction Compared to Cast Aluminum | Key Performance Specifications |

|---|---|---|---|---|

Lower Arms | 6061 | 25% lighter | High strength, high toughness, improved vibration reduction, reliable internal quality | |

Upper Arms | 6061 | 35%-40% lighter | 25% lighter | High strength, high toughness, improved vibration reduction, reliable internal quality |

Cross Beams | 6061 | 35%-40% lighter | 25% lighter | High strength, high toughness, improved vibration reduction, reliable internal quality |

Steering Knuckles | 6061 | 35%-40% lighter | 25% lighter | High strength, high toughness, improved vibration reduction, reliable internal quality |

Disc Brake Jaws | 6061 | 35%-40% lighter | 25% lighter | High strength, high toughness, improved vibration reduction, reliable internal quality |

Forged aluminium components in suspension systems support multi-axis load paths and complex geometries. This design flexibility allows manufacturers to meet strict safety and performance standards. The trend toward lightweighting in the automotive industry drives the adoption of aluminium forging for suspension parts, improving vehicle dynamics and compliance with environmental regulations.

Chassis Components

Chassis components represent another critical area for aluminium forging in automotive applications. Manufacturers use forged aluminium for side rails, crossmembers, and subframes to achieve high strength and structural integrity. Experimental impact tests show that forged or cast aluminium chassis parts sustain less deformation under impact compared to traditional steel weldments. For example, steel rails dent easily, while aluminium castings and forgings maintain their shape, preserving cabin integrity.

Finite element simulations reveal that composite aluminium foam structures integrated into chassis beams absorb impact energy efficiently. The multi-layer aluminium skin and foam crush sequentially, limiting intrusion into vital areas such as battery packs. This design increases total energy absorption by over 40% compared to conventional body structures. Vehicles equipped with forged aluminium chassis components consistently achieve top crash safety ratings from organizations like NHTSA and Euro NCAP. The lightweight nature of forged aluminium components supports vehicle efficiency without sacrificing crashworthiness.

Engine and Transmission

Engine parts and transmission components benefit greatly from aluminium forging. Automotive manufacturers produce cylinder heads, connecting rods, and pistons using forged aluminium. Transmission systems feature forged gears and shift forks. These high-performance components require high strength, heat resistance, and corrosion resistance to withstand demanding operating conditions.

Engine parts commonly made from forged aluminium include:

Cylinder heads

Connecting rods

Transmission parts made from forged aluminium include:

Gears

Shift forks

Forged aluminium components in engines and transmissions contribute to improved performance and fuel efficiency. The forging process eliminates porosity and aligns the grain structure along stress lines, enhancing durability and fatigue resistance. Aluminium’s excellent thermal conductivity aids in heat dissipation, supporting the reliability of engine parts and transmission systems.

Performance Benefits

The applications of aluminum forging in automotive extend beyond individual parts to overall vehicle performance. Forged aluminium components reduce vehicle weight, which directly improves fuel economy and lowers emissions. Automakers increasingly use aluminium forgings to meet stringent fuel economy and emission standards. Replacing steel wheels with forged aluminium wheels can reduce vehicle weight by up to 20%, resulting in nearly a 10% improvement in fuel efficiency and a reduction of approximately 5 grams of CO2 emissions per kilometer. Each 10% reduction in vehicle weight can improve fuel economy by 6% to 8%.

Forged aluminium components offer superior strength-to-weight ratio, impact resistance, and heat dissipation. These properties enhance handling, extend electric vehicle range, and support emission reduction goals. The durability and lifespan of forged aluminium automotive components surpass those of cast or machined alternatives. The forging process produces denser, more resilient parts with controlled grain structure and minimal material waste.

Aspect | Forged Aluminum Components | Cast Aluminum Components | Machined Components |

|---|---|---|---|

Grain Structure | Controlled, aligned along stress lines, enhancing strength, impact resistance, and fatigue endurance | Random, uncontrollable, leading to weak points | Does not improve grain structure |

Porosity | Eliminated through forging, resulting in denser, more resilient parts | Susceptible to porosity, causing weak points | N/A |

Strength and Durability | Superior strength-to-weight ratio, robust under operational forces | Lower strength due to porosity and grain structure issues | Depends on base material, but machining does not enhance strength |

Corrosion Resistance | Higher corrosion resistance, contributing to longer lifespan | Lower corrosion resistance | Depends on material, no enhancement from machining |

Thermal Conductivity | High, aiding in heat dissipation critical for EV components | Lower thermal conductivity | N/A |

Material Waste | Minimal due to near-net shape process | N/A | Higher due to subtractive process |

Typical Automotive Applications | Motor casings, gearbox components, wheels, suspension parts, battery housings | Various, but less ideal for critical load-bearing parts | Used for finishing or complex shapes, less efficient for large-scale production |

Forged aluminium components such as motor casings, gearbox parts, wheels, suspension arms, and battery housings demonstrate exceptional durability and reliability. These parts protect critical systems, improve handling, and support the transition to electric vehicles. The automotive industry continues to prioritize aluminium forging for high-stress and shock points, ensuring long-lasting performance and safety.

Note: The ongoing shift toward forged aluminium components in automotive applications reflects the industry’s commitment to lightweighting, improved performance, and enhanced safety. Manufacturers recognize the value of aluminium forging in delivering high strength, durability, and efficiency across a wide range of vehicle systems.

Aerospace Aluminum Forgings

Structural Components

Aerospace aluminum forgings play a vital role in the construction of aircraft structural parts. Engineers select these forgings for critical load-bearing components due to their high strength, durability, and reliability. The 7xxx series alloys, such as 7075 and 7050, are widely used for fuselage frames and airplane wings. These alloys deliver ultra-high tensile strength, often exceeding 570 MPa, and maintain performance after heat treatments like T6 and T7.

Common structural components produced with aerospace aluminum forgings include:

Fuselage frames

Wing spars and ribs

Bulkheads

Window frames

Fairing joints

Large-sized forgings, sometimes with thicknesses over 150mm, ensure uniform mechanical properties across the entire part. This uniformity is essential for aircraft structural parts that must withstand high loads and repeated stress cycles. Using large integral forgings reduces the number of parts, lowers assembly costs, and improves damage tolerance. About 7% of all aluminum used in commercial aircraft comes from forgings, primarily for these major structural elements.

Note: Aerospace aluminum forgings provide the combination of high strength, plasticity, fracture toughness, and fatigue resistance required for modern aircraft. These properties support safer, more fuel-efficient flights and longer service intervals.

Landing Gear

Landing gear struts and supports represent some of the most demanding applications for aerospace aluminum forgings. These components must absorb the shock of takeoff and landing while supporting the full weight of the aircraft. Forged aluminum offers a superior strength-to-weight ratio, making landing gear lighter and improving overall fuel efficiency. The forging process aligns the grain structure, increasing strength and fatigue resistance compared to cast or machined parts.

Key advantages of aerospace aluminum forgings in landing gear:

High corrosion resistance for reliability in harsh environments

Minimal internal voids and porosity, ensuring structural integrity

Less deformation at high temperatures

Forged aluminum landing gear components outperform those made from steel or cast metals. They maintain structural integrity over thousands of landings, reducing the risk of failure. The combination of high strength and low weight makes aerospace aluminum forgings the preferred choice for landing gear struts in both commercial and military aircraft.

Property | Cast Aluminum Landing Gear | |

|---|---|---|

Tensile Strength | Lower | |

Fatigue Strength | 37% higher | Lower |

Yield Strength | 44% higher | Lower |

Grain Structure | Random, porous | |

Porosity | Minimal | Higher |

Engine Parts

Aerospace aluminum forgings are essential for engine parts that demand high strength, fatigue resistance, and precise tolerances. Manufacturers use these forgings for engine mounts, turbine blades, and structural fittings. The refined grain structure from forging enhances tensile and yield strength, shock resistance, and dimensional stability. Forged aluminum components eliminate internal defects, resulting in greater durability and longer service life.

Typical engine parts produced with aerospace aluminum forgings:

Engine mounts

Turbine blades

Compressor disks

Structural engine fittings

These components must meet strict safety and performance standards. The lightweight nature of aerospace aluminum forgings helps reduce overall aircraft weight, leading to improved fuel efficiency and lower operating costs. The process also allows for complex shapes and tight tolerances, supporting advanced engine designs.

Rocket and Missile Applications

Aerospace aluminum forgings extend beyond aircraft to rockets and missiles. Engineers use these forgings for missile shells, propulsion components, control systems, and launch rails. The material’s high strength-to-weight ratio is crucial for maximizing missile range and payload capacity. Aluminum forgings provide the durability needed to withstand vibration, impact, and extreme temperatures during launch and flight.

Feature/Requirement | |

|---|---|

Components Used | Missile shells, propulsion components, control and guidance components, launch rails |

Key Advantages | Lightweight, high strength-to-weight ratio, corrosion resistance, heat resistance, precision |

Mechanical Properties | Improved tensile strength, fatigue resistance, dimensional accuracy |

Environmental Durability | Corrosion resistance for long-term reliability |

Thermal Performance | Heat resistance suitable for high engine temperatures |

Application Examples | Rocket structures (bulkheads, cones, rings), missile shells, nozzles, launch box guide rails |

Processing Benefits | Enhanced mechanical properties via advanced forging and heat treatment |

Industry Standards | Meets aerospace and defense high reliability and performance requirements |

Aluminum forgings in these applications protect sensitive internal components and maintain structural stability in complex environments, such as naval or space settings. The corrosion resistance of aerospace aluminum forgings ensures long-term reliability, even in harsh conditions.

Alloys and Mechanical Properties

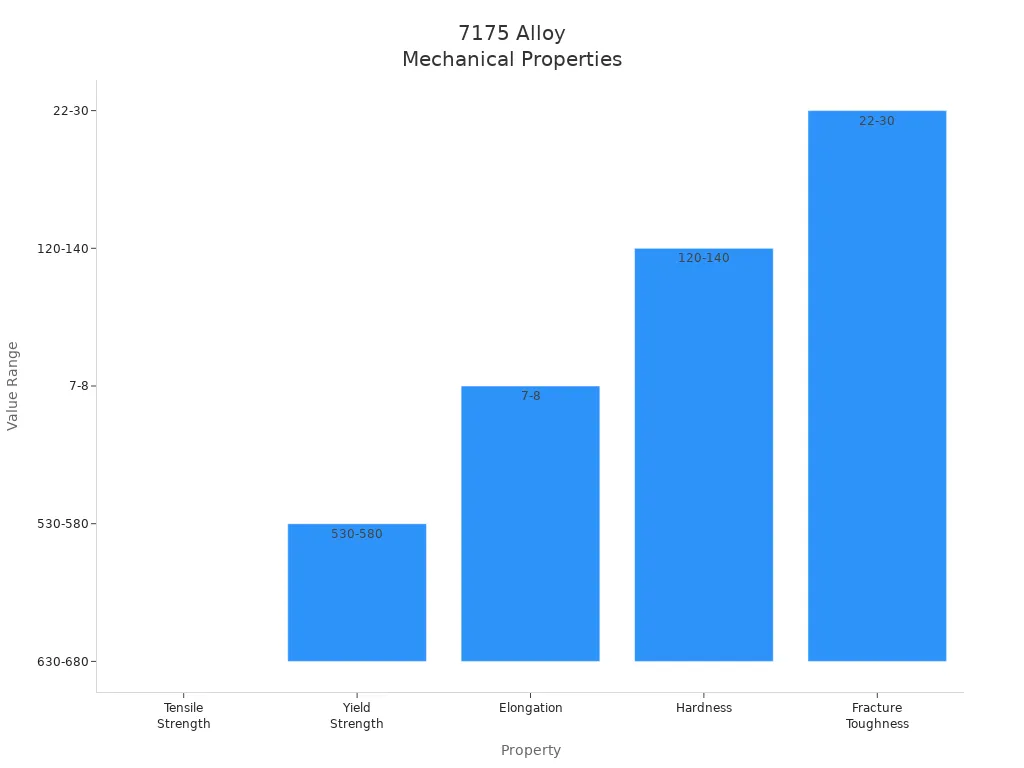

The aerospace industry relies on advanced alloys for critical forgings. The 7175 aluminum alloy, especially in T6 and T74 tempers, is a top choice for aerospace aluminum forgings. This alloy delivers high tensile strength (630–680 MPa), yield strength (530–580 MPa), and excellent fracture toughness. The T74 temper offers improved stress corrosion resistance, making it suitable for aircraft front sections, window frames, and control parts.

Property | Typical Values |

|---|---|

Density | 2.81 g/cm³ |

Melting Point | 463 °C |

Hardness | 120 – 140 HB |

Yield Strength | 530 – 580 MPa |

Tensile Strength | 630 – 680 MPa |

Elongation | 7 – 8 % |

Fracture Toughness | 22 – 30 J/cm² |

T6 Temper: Maximizes strength and hardness through artificial aging.

T74 Temper: Enhances high temperature performance and crack resistance.

Aerospace aluminum forgings made from these alloys provide the high strength, toughness, and corrosion resistance required for demanding applications. The refined grain structure and elimination of porosity result in longer service life and better fatigue performance compared to cast or machined parts.

Aerospace aluminum forgings enable the production of lighter, stronger, and more reliable aircraft structural parts, landing gear struts, engine parts, and rocket components. These advantages drive innovation in aerospace design and support the industry’s goals for safety, efficiency, and sustainability.

Aluminum Forging vs Other Methods

Forging vs Casting

Aluminum forging and casting serve different needs in manufacturing. Forged aluminum parts excel in strength and fatigue resistance because the forging process aligns the grain structure and reduces internal defects. Cast aluminum, while capable of producing complex shapes and thin walls, often contains porosity and random grain structures that weaken the material. The following table highlights key differences:

Attribute | Forged Aluminum | Cast Aluminum |

|---|---|---|

Tensile & Yield Strength | High, due to grain refinement and deformation | Moderate to low, susceptible to porosity |

Fatigue Resistance | Excellent, continuous grain flow | Low, internal voids weaken durability |

Grain Structure | Continuous and aligned | Random and fragmented |

Internal Defects | Very low porosity and inclusions | Higher likelihood of porosity and cracks |

Shape Complexity | Limited to simple, symmetric shapes | Supports intricate, thin-walled, complex parts |

Surface Finish | Rough, requires machining | Smooth as-cast surface, less post-processing |

Weight | Lightweight with better strength-to-weight ratio | Lightweight |

Suitability | High-load, cyclic stress, extreme environments | Non-critical parts, complex geometries |

Casting offers cost advantages for high-volume production, especially when complex shapes are needed. However, forged parts provide superior mechanical properties, making them the preferred choice for safety-critical automotive and aerospace components.

Forging vs Machining

Forging and machining both play important roles in component manufacturing. Forging produces parts with enhanced metallurgical properties, such as improved fatigue strength and durability. Machining, in contrast, delivers precise tolerances and smooth surface finishes. Manufacturers often use machining to finish forged parts, achieving the required dimensional accuracy.

Forged aluminum parts typically have less precise tolerances than machined parts. Machining achieves close tolerances and repeatability, which are essential for assemblies that demand tight control. However, machining alone generates more material waste and incurs higher labor costs, especially for large or complex parts.

Why Choose Forging

Engineers select aluminum forging for applications where strength, reliability, and safety matter most. Forged parts withstand high loads, repeated stress, and harsh environments. The forging process minimizes internal defects, ensuring consistent performance over time. While forging involves higher initial costs and requires additional machining for tight tolerances, economies of scale in high-volume production help reduce per-unit expenses.

Forged aluminum remains the top choice for critical automotive and aerospace parts, where failure is not an option. The combination of superior mechanical properties and long-term durability justifies the investment in forging technology.

Advantages of Aluminum Forgings

Strength and Durability

Aluminum forgings deliver superior strength and toughness, making them ideal for safety-critical parts in automotive and aerospace industries. The forging process improves the metal grain structure, resulting in high-strength components that withstand impact and repeated stress. Turbine blades, landing gear, and connecting rods benefit from this exceptional durability. These parts maintain reliability under extreme conditions, supporting both safety and long service life.

Advantage | Explanation |

|---|---|

Superior Strength | Aluminum forgings offer better wear and impact resistance, essential for engine and suspension parts. |

Exceptional Durability | Enhanced grain structure ensures long-lasting performance in demanding environments. |

Lightweight Design

Engineers value aluminum forgings for their lightweight nature. Lightweight forged aluminum alloys enable the production of reduced weight parts without sacrificing strength. This advantage leads to improved fuel efficiency and better handling in vehicles and aircraft. The superior strength-to-weight ratio of these components supports advanced designs and helps manufacturers meet strict emission standards.

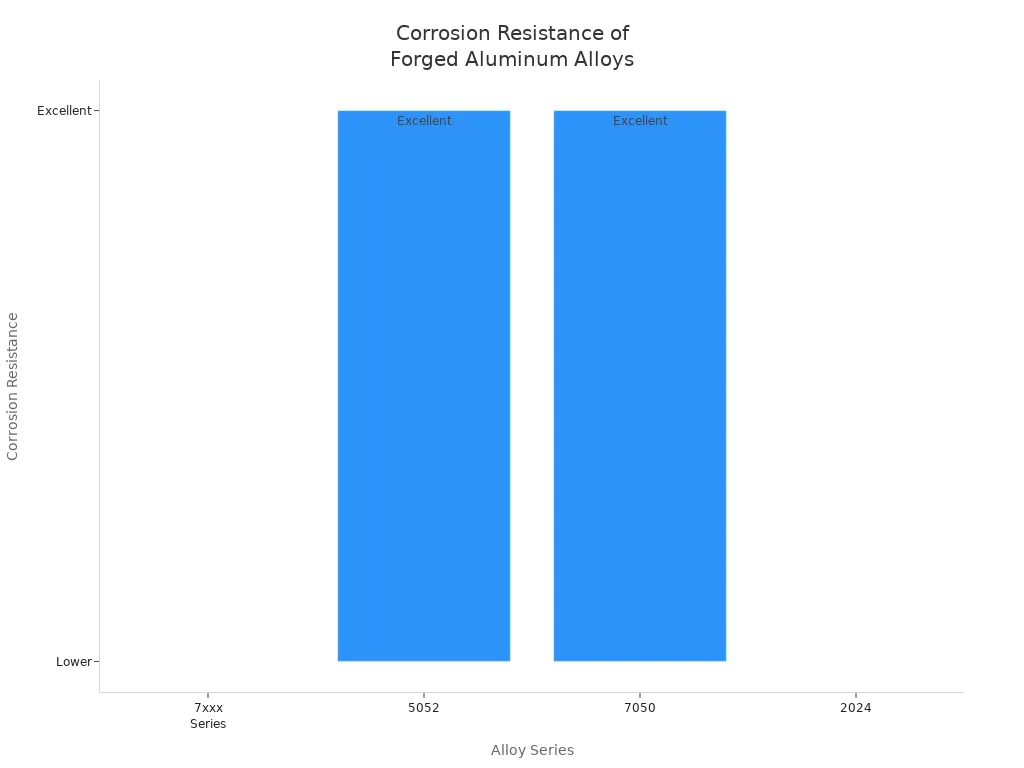

Corrosion Resistance

Aerospace-grade aluminum forgings exhibit high corrosion resistance, which is vital for longevity and safety in harsh environments. Alloying elements such as zinc, magnesium, and copper enhance this property, making these forgings suitable for aircraft wings, fuselages, and marine applications. The table below highlights the balance between corrosion resistance and strength among common alloys:

Alloy Series | Key Alloying Elements | Corrosion Resistance | Strength | Notes |

|---|---|---|---|---|

7xxx Series (e.g., 7075) | Zinc, Magnesium, Copper | Lower; needs treatment | Extremely high | Requires coatings or heat treatments |

5052 | Magnesium, Chromium | Excellent | Lower | Good weldability and fatigue strength |

7050 | Zinc, Magnesium, Copper, Zirconium | Excellent | High | Improved over 7075 |

2024 | Copper, Magnesium | Lower | Moderate to high | Often clad for protection |

Precision and Complexity

Aluminum forgings support precision engineering and the creation of complex shapes. Advanced methods such as closed die forging and 3D forging allow manufacturers to produce components with tight tolerances and fine surface finishes. This capability ensures that parts meet stringent industry standards for reliability and performance. The integration of CAD-to-forging processes further enhances design flexibility and quality.

Aluminum forging enables:

Complex geometries with high precision

Superior fatigue resistance and fracture toughness

Reliable performance in structural and load-bearing applications

Sustainability

Aluminum forgings offer significant environmental benefits. Direct recycling through hot press forging reduces energy consumption and greenhouse gas emissions compared to traditional melting-based recycling. This process lowers the global warming potential by up to 69.2%. The solid-state recycling approach conserves material and energy, making aluminum forgings a sustainable choice for manufacturers. Reduced material waste and improved recyclability support both cost savings and corporate responsibility.

Aluminum forgings combine strength, reduced weight, corrosion resistance, precision, and sustainability. These advantages drive improved safety, performance, and cost-effectiveness in automotive and aerospace industries.

Aluminum forging drives innovation in automotive and aerospace technology. Engineers rely on its strength, lightweight properties, and corrosion resistance to meet demanding performance standards.

Industry trends highlight rapid growth in electric vehicles and aircraft, fueled by advanced alloys and precision forging techniques.

Automation, AI-driven controls, and sustainability initiatives shape future manufacturing.

Aluminum forging will remain essential as manufacturers pursue safer, more efficient, and eco-friendly solutions. Ongoing research and digital transformation promise even greater advancements in the years ahead.

FAQ

What makes aluminum forging superior to casting for critical components?

Forged aluminum parts show higher strength and better fatigue resistance than cast parts. The forging process aligns the grain structure and reduces internal defects. Engineers choose forging for safety-critical automotive and aerospace applications.

Which aluminum alloys are most common in aerospace forging?

Aerospace manufacturers often use 7075, 7050, and 7175 alloys. These alloys provide high tensile strength, excellent fatigue resistance, and good corrosion protection. They meet strict industry standards for structural and engine parts.

How does aluminum forging contribute to vehicle weight reduction?

Aluminum forgings replace heavier steel or cast iron parts. This switch reduces overall vehicle weight by up to 40%. Lighter vehicles improve fuel efficiency, handling, and emissions performance.

Can aluminum forgings withstand extreme temperatures?

Yes. Forged aluminum components maintain strength and stability at high temperatures. This property makes them suitable for engine parts, landing gear, and aerospace structures exposed to thermal stress.

Are aluminum forgings environmentally friendly?

Aluminum forgings support sustainability. The process uses less energy and produces minimal waste. Recycled aluminum can be forged directly, reducing environmental impact and supporting green manufacturing goals.