Forged Pistons vs Cast Pistons Which Delivers Better Performance

Forged piston generally delivers better performance in high-stress and high-temperature conditions, such as motorsport or forced induction applications. Pistons play a vital role in the engine by managing combustion forces, heat, and motion. Recent engineering studies show that advanced designs and materials like optimized aluminum alloys and specialized coatings help pistons reduce friction, improve combustion, and boost engine reliability. When choosing between piston types, factors such as strength, durability, heat resistance, cost, and intended application make a significant difference for engineers, buyers, and enthusiasts.

Pistons and Performance

Engine Role

Pistons serve as the heart of every engine. They move up and down inside the cylinder, turning the energy from burning fuel into mechanical motion. This movement drives the crankshaft, which then powers the wheels or other machinery. Each piston must handle intense pressure and heat during every cycle. The design and material of the piston affect how well the engine can convert fuel into useful work.

A piston’s job does not stop at moving up and down. It also seals the combustion chamber, keeping gases from escaping. This seal is crucial for maintaining compression, which directly influences how much power the engine can produce. If the seal fails, the engine loses efficiency and performance drops. Pistons also help control oil flow and reduce friction between moving parts. Engineers focus on these roles when designing pistons for different types of engines.

Impact on Performance

The design of a piston has a direct effect on engine performance. Modern pistons use advanced features like gapless second ring technology, ceramic top coatings, and dimpled surfaces. These features improve combustion by sealing the cylinder better and reducing heat loss. For example, dimpled surfaces, inspired by golf ball technology, help optimize airflow during the compression stroke. This leads to more complete burning of fuel and better power output.

Dyno testing shows that these innovations can increase torque by as much as 210 ft-lbs without changing the engine control module or fuel injectors. Engines with these pistons also see a 20-25% boost in fuel efficiency and lower exhaust gas temperatures. These improvements mean the engine delivers more horsepower and better bottom-end power. Drivers notice smoother acceleration and stronger response across different speeds.

Piston design also affects how long an engine lasts. Stronger materials and better coatings help pistons resist wear and heat damage. This means the engine can run at high performance levels for longer periods without failure. In motorsports and high-performance vehicles, these benefits are essential. Even in daily driving, better pistons lead to more reliable engines and lower maintenance costs.

Note: Choosing the right piston design can transform an ordinary engine into a high-performance machine. Engineers and enthusiasts often look for these features when upgrading or building engines for specific needs.

Cast Pistons Overview

Manufacturing

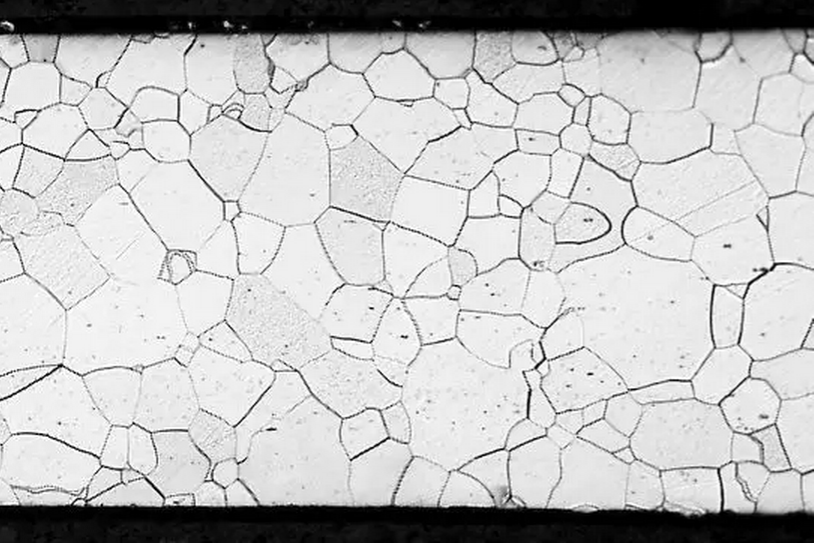

Manufacturers create cast pistons by pouring molten aluminum alloy into a precision mold. This process allows the metal to take the exact shape of the piston, including complex features like ring grooves and pin bosses. The casting process uses alloys with specific properties to meet the demands of different engines.

Most cast pistons use aluminum-silicon alloys. The silicon content usually ranges from 8% to 16%.

Hypereutectic alloys, such as the 390 alloy, contain higher silicon levels. These alloys help pistons run with tighter clearances and perform better at higher temperatures.

Higher silicon content increases wear resistance and reduces thermal expansion. This makes cast pistons more durable and stable during engine operation.

Manufacturers often add coatings to cast pistons. These coatings improve wear resistance and help manage heat.

The casting process supports mass production. It allows companies to produce large numbers of pistons quickly and at a lower cost compared to other methods.

Key Features

Cast pistons offer several advantages for many types of engines. Their manufacturing process makes them cost-effective, which appeals to both automakers and consumers. Cast pistons tend to be lighter than older steel or iron designs, which helps improve engine efficiency. The high silicon content in their alloys reduces friction and allows for quieter operation. This makes them ideal for engines where noise and smoothness matter.

Note: Cast pistons provide good performance for most daily driving needs. Their design supports reliable operation in standard temperature and pressure ranges.

However, cast pistons have some limitations. They do not handle extreme stress or high temperatures as well as forged pistons. In high-performance or racing engines, cast pistons may wear out faster or fail under heavy loads.

Typical Uses

Cast pistons appear most often in original equipment manufacturer (OEM) engines for passenger cars and light trucks. They also see wide use in moderate performance vehicles and motorcycles. Industry reports show that cast iron pistons dominate heavy-duty diesel engines in commercial vehicles like trucks, buses, and industrial machinery. These vehicles rely on cast pistons for their durability, thermal resistance, and cost-effectiveness during long hours of operation.

Automakers choose cast pistons for engines that need to balance cost, reliability, and efficiency. For most drivers, cast pistons deliver dependable performance and low maintenance over the life of the engine.

Forged Pistons Explained

Forging Process

Forged Pistons use a specialized forging process that transforms raw aluminum into high-performance engine components. Manufacturers begin by heating a metal billet to temperatures between 1900°F and 2300°F. They then position the billet between dies, aligning the grain direction for maximum structural integrity. A fuller tool segments the metal, focusing on one section at a time. Next, powerful presses compress or hammer the metal between the dies, shaping the piston.

This process refines and contours the grain flow inside the metal. The repeated pressure reduces porosity and aligns the grain structure. As a result, forged pistons gain exceptional strength, durability, and fatigue resistance. These qualities make them ideal for high-performance and racing engines, where reliability under stress is critical.

Material Choices

Engineers select specific aluminum alloys for forged pistons to match the demands of different applications. Two popular choices are 2618 and 4032 alloys. The 2618 alloy contains low silicon, which gives it high strength and ductility. This alloy tolerates extreme temperatures and is often used in racing engines that face intense heat and pressure. The 4032 alloy has a higher silicon content, which reduces thermal expansion and allows for tighter clearances. This makes it suitable for high-performance street engines that need both durability and smooth operation.

The choice of material affects how the piston handles heat, pressure, and wear. For example, 2618 alloy pistons expand more when hot, so they require larger cold clearances. In contrast, 4032 alloy pistons expand less, making them better for engines that run at a wide range of temperatures. Both alloys support the advanced designs needed for modern high-performance engines.

Performance Benefits

Forged pistons deliver several key performance advantages in demanding engine environments. Their superior strength allows them to withstand the extreme cylinder pressures found in turbocharged, supercharged, or nitrous-boosted engines. Manufacturers often design these pistons with thicker crowns, skirts, and ring lands to handle the added stress. Reinforced wrist pins and pin bosses resist flexing and support higher loads.

Design optimizations, such as asymmetrical skirts and larger-radius contours under the crown, help reduce weight while maintaining stability. These features also improve heat distribution and minimize stress concentrations. Many forged pistons include thermal crown coatings, like ceramic, to reflect heat back into the combustion chamber. This improves turbo spool-up and extends piston life.

Note: Forged pistons maintain a reliable ring seal, reduce frictional losses, and support higher horsepower. These benefits make them the top choice for high-performance, racing, and boosted engines. Drivers and engineers trust forged pistons to deliver consistent performance and durability, even under the harshest conditions.

Common Applications

Forged pistons play a vital role in many high-performance engines. Engineers and manufacturers choose them for applications where strength, durability, and heat resistance are critical. The most common use of forged pistons appears in motorsport disciplines. Drag racing, circuit racing, and rally events all demand engines that can handle extreme pressure and high RPMs. In these environments, forged pistons provide a superior strength-to-weight ratio. They also tolerate shock loading from detonation and can absorb debris without catastrophic failure. This makes them the top choice for race teams seeking maximum power and reliability.

Many racing engines use forged pistons made from 2618 aluminum alloy. This material offers high ductility and strength, which helps the piston survive the intense conditions found in professional motorsport. Teams in drag racing and endurance racing often specify 2618 alloy pistons because they can withstand high compression ratios and extreme cylinder pressures. For street performance cars or vehicles that see occasional track use, 4032 alloy forged pistons are popular. These pistons offer better noise and wear characteristics, making them suitable for engines that need to balance performance with daily drivability.

Automotive tuners and performance shops also rely on forged pistons when upgrading engines for turbocharging or supercharging. Forced induction increases cylinder pressure and temperature, which can quickly damage standard cast pistons. By using forged pistons, builders ensure the engine can handle the extra power without failure. High-revving motorcycle engines, off-road vehicles, and marine engines benefit from the same advantages. These engines often operate in harsh conditions where reliability is essential.

Forged Pistons have also found a place in modern hybrid and electric motorcycle platforms. As these vehicles push for higher power density and lighter weight, forged pistons help achieve both goals. Some industrial engines, such as those used in aviation or marine applications, use forged pistons to guarantee long-term durability and consistent performance.

Note: Forged pistons are not limited to racing. They appear in any engine where engineers demand the highest levels of strength, heat resistance, and fatigue life. Their use continues to expand as technology advances and performance expectations rise.

Forged Pistons vs Cast Pistons

Strength

Strength plays a crucial role in how pistons handle the intense forces inside an engine. Forged pistons show greater strength than cast pistons because of their unique manufacturing process. The forging process compresses the metal’s grain structure, which makes the piston more resistant to cracking and deformation. Cast pistons, on the other hand, have a random grain structure that can include tiny air pockets. These pockets make cast pistons weaker under high pressure.

Engineers often choose forged pistons for high-performance engines that run at high RPMs or use forced induction. These engines create much higher cylinder pressures. Forged pistons can handle these conditions without failing. Cast pistons work well in standard engines, but they may break or crack if exposed to extreme loads. Real-world tests show that forged pistons can be up to 30% stronger than cast pistons. This greater strength allows them to survive in racing, turbocharged, and supercharged engines.

Tip: When building an engine for motorsport or heavy-duty use, always consider the strength of the piston material. Forged pistons offer the best protection against mechanical failure.

Durability

Durability measures how long a piston can last under repeated stress and heat cycles. Forged pistons are more durable than cast pistons in high-performance applications. The forging process removes most of the internal flaws that can cause early failure. This makes forged pistons more durable and able to withstand millions of combustion cycles.

Cast pistons provide good durability for daily driving and moderate performance. They resist wear and tear in normal conditions. However, when exposed to high temperatures and pressures, cast pistons may develop cracks or lose their shape. Forged pistons remain more durable in these harsh environments. Many race teams and performance builders report that forged pistons last longer and require fewer replacements during a racing season.

A table below compares the durability of both types:

Attribute | Forged Pistons | Cast Pistons |

|---|---|---|

Durability | More durable | Good for daily use |

Fatigue Resistance | Excellent | Moderate |

Lifespan (Racing) | High | Lower |

Heat Resistance

Heat resistance is another key factor in piston selection. Engines generate extreme heat during combustion. Forged pistons handle this heat better than cast pistons. The dense grain structure in forged pistons allows them to absorb and transfer heat more efficiently. This helps prevent hot spots and reduces the risk of piston failure.

Cast pistons use alloys with higher silicon content to improve their heat resistance. These alloys help cast pistons perform well in standard engines. However, in high-performance engines, the heat can exceed what cast pistons can handle. Forged pistons maintain their shape and strength even at very high temperatures. This makes them the preferred choice for turbocharged, supercharged, and racing engines.

Note: For engines that run at high temperatures or use forced induction, forged pistons provide the best heat resistance and reliability.

Weight

Engineers often focus on weight when comparing forged pistons and cast pistons. The weight of a piston affects how quickly an engine can accelerate and how smoothly it runs at high speeds. Lighter pistons reduce the load on the connecting rods and crankshaft. This helps the engine rev faster and improves throttle response.

Forged pistons allow for more precise shaping and thinner walls without losing strength. Manufacturers can remove extra material from non-critical areas. This process creates a lighter piston that still handles high stress. In racing engines, every gram counts. Teams choose forged pistons to gain an edge in acceleration and engine response.

Cast pistons usually have thicker walls to maintain strength. The casting process does not align the metal grains, so engineers add more material for safety. This extra material increases the overall weight. Heavier pistons can slow down engine response and increase vibration at high RPMs.

A comparison table helps show the differences:

Attribute | Forged Pistons | Cast Pistons |

|---|---|---|

Weight | Lighter, optimized | Heavier, less optimized |

Engine Response | Faster | Slower |

High RPM Stability | Better | Lower |

Tip: Lighter pistons help engines rev higher and run smoother. This is why many performance engines use forged pistons instead of cast pistons.

Cost

Cost is a major factor for buyers and engineers. Forged pistons cost more to produce than cast pistons. The forging process uses special equipment and takes more time. Each piston needs extra machining and finishing steps. These steps add to the final price.

Cast pistons are less expensive because the casting process supports mass production. Factories can make thousands of cast pistons quickly. This lowers the cost per unit. Automakers often choose cast pistons for standard vehicles to keep prices low.

The price difference becomes clear in performance upgrades. Racing teams and engine builders pay more for forged pistons because they want better strength and durability. For daily driving or moderate performance, cast pistons offer a good balance between cost and reliability.

A quick summary:

Forged pistons: Higher cost, best for high-performance and racing engines.

Cast pistons: Lower cost, ideal for mass-market and standard engines.

Note: Buyers should match the piston type to their budget and performance goals. Cast pistons work well for most drivers who do not need extreme power or durability.

Performance in Real-World Scenarios

Daily Driving

Most drivers use their vehicles for commuting, errands, and family trips. In these situations, engines rarely face extreme stress or high temperatures. Cast pistons work well for daily driving because they offer a good balance of cost, reliability, and quiet operation. Automakers often choose cast pistons for standard cars and light trucks. These pistons help engines run smoothly and quietly, which many drivers prefer.

Cast pistons also support lower oil consumption and less engine noise. Their high silicon content reduces friction and allows for tighter clearances. This design helps engines last longer and require less maintenance. For most people, cast pistons provide dependable performance for many years.

Tip: For daily driving, cast pistons usually meet all the needs for reliability and efficiency. They keep maintenance costs low and help engines run quietly.

However, some drivers want more power or plan to modify their engines. In these cases, forged pistons can offer extra strength and durability. They handle higher loads and temperatures, which makes them a good choice for those who want serious performance upgrades in their daily vehicles.

Racing and High RPM

Racing engines face extreme conditions. They run at high RPMs and experience intense cylinder pressures. In this environment, forged pistons become essential. The forging process creates a dense grain structure that resists cracking and fatigue. High-performance engines in motorsport rely on forged pistons to survive long races and repeated stress.

Teams in drag racing, circuit racing, and rally events choose forged pistons for their strength and heat resistance. These pistons allow engines to run at higher compression ratios and produce more horsepower. Forged pistons also support advanced features like thermal barrier coatings and reinforced ring lands. These upgrades help engines maintain peak performance throughout a race.

A comparison table shows the differences:

Scenario | Best Piston Type | Key Benefits |

|---|---|---|

Daily Driving | Cast Pistons | Quiet, efficient, reliable |

Racing/High RPM | Forged Pistons | Strong, heat-resistant, durable |

Note: Racing engines demand the highest level of durability and strength. Forged pistons deliver the performance needed for victory on the track.

Forced Induction

Forced induction engines use turbochargers or superchargers to increase air pressure in the cylinders. This setup boosts power but also raises cylinder temperatures and pressures. Standard cast pistons may not survive these harsh conditions. Forged pistons provide the strength and heat resistance needed for forced induction applications.

Many high-performance street cars and racing vehicles use forced induction to achieve greater horsepower. Forged pistons handle the extra stress and prevent failures like cracking or ring land breakage. They also allow for higher boost levels, which means more power for the driver.

Callout: When building a turbocharged or supercharged engine, forged pistons are the best choice for reliability and long-term performance.

Some tuners and engine builders report that forged pistons help reduce oil consumption and maintain a better ring seal under boost. This leads to more consistent power and longer engine life. High-performance engines with forced induction often rely on forged pistons to reach their full potential.

Electric and Hybrid Engines

Electric and hybrid engines have changed the way engineers think about pistons. These engines often use smaller, lighter components to improve efficiency and reduce emissions. In hybrid systems, the engine may start and stop many times during a single trip. This cycle puts unique stress on the pistons.

Forged pistons have become popular in high-performance hybrid and electric motorcycle engines. Manufacturers choose forged pistons for their strength and ability to handle rapid temperature changes. For example, a leading electric motorcycle company in Southeast Asia switched to forged pistons made from 2618 aluminum alloy. The company reported a 27% increase in engine life and a 15% boost in torque handling. These results show that forged pistons can improve both durability and power in modern hybrid platforms.

Cast pistons still appear in many standard hybrid vehicles. Automakers use them because they offer quiet operation and low cost. Cast pistons also help reduce engine noise, which is important in electric and hybrid cars where the engine runs less often. Drivers notice less vibration and smoother starts when the engine turns on.

However, as electric and hybrid engines become more powerful, the demand for better performance grows. Forged pistons support higher compression ratios and withstand the extra heat from frequent start-stop cycles. They also allow engineers to design lighter pistons, which helps the engine respond faster and use less energy.

Tip: When building or upgrading a hybrid or electric engine for higher output, forged pistons provide the best mix of strength, heat resistance, and long-term reliability.

Noise and oil consumption matter in these engines. Forged pistons with advanced coatings can reduce friction and keep oil use low. This helps the engine run cleaner and last longer. In summary, forged pistons deliver the performance and durability needed for the next generation of electric and hybrid vehicles, especially in applications where power and reliability are critical.

Choosing Pistons

Assessing Needs

Selecting the right piston starts with understanding the engine’s purpose and performance goals. Every engine build has unique requirements. Some engines need to handle daily driving, while others must survive the demands of racing or forced induction. The intended use shapes every decision about piston material, design, and features.

Engine builders should consider the power level and RPM range.

The choice between cast, hypereutectic, or forged pistons depends on durability needs.

Forged 2618 alloy pistons work well for high power and extreme conditions because they resist fractures.

Forged 4032 alloy pistons offer tighter clearances and better wear resistance, making them a better choice for street and strip applications.

Hypereutectic cast pistons provide good wear resistance and thermal benefits but less ductility.

Piston weight affects how quickly the engine responds and how much stress it puts on rods and the crankshaft.

Compression height must match the engine build, especially in stroker engines.

Features like valve clearance notches, ring groove compatibility, pin retention methods, and coatings all play a role in performance and durability.

Lightweight forged pistons often require custom balancing during assembly.

Setting realistic expectations based on the application and budget helps avoid overbuilding or underbuilding.

Manufacturer technical support can help with race-level piston selection.

Tip: Matching piston features to the engine’s needs ensures reliability and performance. For high-performance builds, forged pistons often become the better choice.

Budget Factors

Budget plays a major role in piston selection. Cast pistons cost less and suit most daily drivers or moderate performance engines. Forged pistons cost more because of their advanced manufacturing process and materials. However, they offer greater strength and durability, which can save money in the long run by reducing the risk of engine failure.

Engineers and buyers should weigh the initial investment against the expected performance and lifespan. Spending more on forged pistons makes sense for engines that face high stress, frequent racing, or forced induction. For standard vehicles, cast pistons provide a reliable and affordable solution. Setting a clear budget helps narrow down options and prevents overspending on unnecessary features.

Note: Investing in quality pistons from a reputable supplier ensures better value and long-term satisfaction.

Customization Options

Forged pistons offer many customization options to meet specific engine requirements. Manufacturers can tailor features such as advanced coatings, specialized skirt designs, and unique dome shapes. These customizations help reduce wear, lower friction, and improve heat dissipation. As a result, the engine gains more horsepower capacity and longer life.

The table below highlights some common forged piston series and their customization features:

Series Name | Forging Type | Performance Application | HP Rating | Key Customization Features and Effects |

|---|---|---|---|---|

Pro Tru Street | Full Round/Slab Side | Mild-Moderate Duty | Up to 750 | ArmorGlide skirt coating reduces friction and wear; as-forged dome design saves machining time. |

RED Series | Strutted | Moderate-Heavy Duty | 1000+ | 2618 alloy for strength and heat dissipation; horizontal slot oiling lowers friction; smooth radius design improves heat dissipation. |

Professional Series | Strutted/Slab Side | Heavy-Severe Duty | 1500+ | Left/right specific pistons; gas ports and pressure seal grooves minimize blow-by; premium materials for maximum performance. |

Engineers can also request features like gas ports, pressure seal grooves, or forced pin oiling. These options help optimize the piston for specific racing or high-performance needs. Working with a supplier that offers technical support, material certification, and thorough testing ensures each piston meets strict quality standards.

Callout: Choosing a supplier with ISO certification and advanced testing equipment guarantees consistent quality and performance. This makes forged pistons a better choice for demanding applications.

Common Failures and Prevention

Skirt Collapse

Skirt collapse happens when the piston skirt—the lower part of the piston that guides it in the cylinder—loses its shape under stress. In high-stress engines, skirt collapse often starts with excessive heat or friction. Cast pistons are more likely to suffer from this problem because their grain structure is random and can contain small air pockets. These weaknesses make the skirt less able to handle repeated loads and high temperatures. When the skirt collapses, the piston may rock in the cylinder, causing noise, loss of compression, and even engine damage.

Forged pistons resist skirt collapse much better. The forging process compresses the metal, creating a dense and aligned grain structure. This structure gives the skirt more strength and flexibility. As a result, forged pistons maintain their shape even after millions of cycles. Their improved durability helps engines run smoothly, even in racing or forced induction setups.

Tip: Engines that run at high RPM or under heavy loads benefit from the extra strength of forged pistons, which helps prevent skirt collapse and extends engine life.

Ring Land Breakage

Ring land breakage is one of the most common failures in high-performance engines. The ring lands are the thin sections of the piston between the grooves that hold the piston rings. In cast pistons, these areas are the weakest points. High cylinder pressures, detonation, or poor tuning can cause cracks to start at the ring lands. Once a crack forms, it can quickly spread, leading to catastrophic piston failure.

Forged pistons offer a strong defense against ring land breakage. Their superior strength and ductility allow them to absorb shock loads and resist cracking. The forging process also improves heat transfer, which helps keep the ring lands cooler and reduces thermal stress. Many forged pistons feature extra mass in the ring pad area, further protecting the ring lands from damage. This design gives a safety margin that cast pistons cannot match.

Cast pistons are more brittle and prone to ring land failure.

Forged pistons withstand detonation and high boost pressures, making them ideal for racing and turbocharged engines.

Cracking and Pitting

Cracking and pitting can occur when pistons face repeated stress or poor combustion conditions. Cast pistons often develop fatigue cracks along grain boundaries, especially in high-RPM or high-power applications. These cracks can grow over time, eventually causing the piston to fail. Pitting, which appears as small holes or surface damage, usually results from hot spots or detonation.

Forged pistons handle these challenges with greater durability. Their dense grain structure resists crack formation and slows crack growth. Better heat dissipation also helps prevent hot spots that cause pitting. In engines where reliability is critical, forged pistons provide peace of mind by reducing the risk of sudden failure.

Note: Choosing forged pistons increases durability and helps prevent common failures like skirt collapse, ring land breakage, and cracking, especially in demanding engine environments.

Summary Table

Quick Comparison

Choosing between forged pistons and cast pistons depends on the engine’s needs. Each type offers unique strengths. The table below highlights the main differences in performance and application.

Attribute | Forged Pistons | Cast Pistons |

|---|---|---|

Material | Solid metal billets compressed under high pressure | Molten metal poured into molds |

Tensile Strength | Higher | Lower |

Heat Resistance | Better | Lower |

Combustion Pressure Tolerance | Can withstand higher pressures and temperatures | Less tolerant |

Durability & Longevity | Superior | Moderate |

Suitability | High-performance, high-revving, high-horsepower engines | Stock or mild performance applications |

Tip: Forged pistons work best in engines that face high stress, such as racing, turbocharged, or high-revving applications. Cast pistons suit daily drivers and standard vehicles.

Forged Piston Series at a Glance

Engineers can choose from several forged piston series, each designed for specific power levels and uses. The table below summarizes popular options:

Series Name | Alloy Type | Forging Type | Application | HP Rating | Key Features |

|---|---|---|---|---|---|

Pro Tru Street | 4032 Aluminum | Full Round/Slab Side | Mild-Moderate Duty | Up to 750 | ArmorGlide coating, as-forged dome, standard rings |

RED Series | 2618 Aluminum | Strutted | Moderate-Heavy Duty | 1000+ | Horizontal slot oiling, smooth radius, GFX rings |

Professional Series | 2618 Aluminum | Strutted/Slab Side | Heavy-Severe Duty | 1500+ | Gas ports, pressure seal grooves, premium rings |

Horizontal slot oiling reduces friction and wear, helping pistons last longer.

ArmorGlide coating and smooth radius designs improve heat dissipation and combustion efficiency.

The Professional Series includes advanced features like gas ports and left/right-specific pistons for a perfect fit in high-stress engines.

Note: When building an engine for motorsport or heavy-duty use, forged pistons with advanced features provide the best protection and performance.

Buyers and engineers should match piston type to engine demands. Forged pistons offer high durability and cost-effectiveness for high-horsepower or heavy-duty engines, while cast pistons suit standard vehicles. The table below highlights expert recommendations:

Piston Type | Durability | Cost-Effectiveness | Best Use |

|---|---|---|---|

Forged Pistons | High | Moderate | Performance, heavy-duty |

Cast Pistons | Moderate | High | Daily driving, stock |

Billet Pistons | Very High | Low | Extreme racing |

Understanding piston technology helps engineers boost reliability, efficiency, and overall engine performance.

FAQ

What are the advantages of aluminum forged pistons compared to cast ones in high-performance engines?

Forged pistons offer significantly higher strength, fatigue resistance, and structural integrity due to the compact grain structure formed during forging. They’re ideal for high-compression, high-RPM, or turbocharged engines. Casting, in contrast, is more prone to porosity and thermal fatigue, making it less suitable for performance-critical applications.

What aluminum alloys do you commonly use for forging pistons, and how do you select the right one?

We mainly use 2618-T6 for extreme-performance or racing applications, and 4032-T6 for street and OEM applications. 2618 has better ductility and high-temperature resistance, while 4032 has lower thermal expansion and better wear resistance. Selection depends on your engine’s load, heat, and life cycle expectations.

Can you supply the complete piston, including CNC machining and surface coating?

Yes, we offer a one-stop solution from forging, heat treatment, precision CNC machining (±0.01mm), to surface coating such as anodizing or graphite-based skirt coating. We also provide 3D measurement reports and full traceability per batch.

Do forged pistons increase engine noise?

Some forged pistons may create more noise, especially when cold. Modern designs and coatings help reduce this effect. Most drivers notice little difference during normal operation.

What is your typical lead time and MOQ for custom forged pistons?

Our typical MOQ is 500 pcs, and the lead time for sampling is 25–35 days, depending on whether CNC is required. We support flexible tooling setups and can handle multi-SKU batches for R&D or performance tuning clients.

Are forged pistons always heavier than cast pistons?

No. Forged pistons often weigh less because manufacturers can remove extra material without losing strength. Lighter pistons help engines rev faster and run smoother.

What is the typical lifespan of a forged piston?

With proper tuning and maintenance, forged pistons can last over 100,000 kilometers. Racing engines may require more frequent checks, but forged pistons offer long service life.