Geschmiedete vs Billet Motorrad gabelbrücken Erklärt

Triple clamps play a critical role in motorcycle stability and steering precision. Forged versions use the forging motorcycle triple clamp process, which compresses heated aluminum to create a strong grain structure. Billet triple clamps, on the other hand, are machined from a solid block for maximum rigidity. Riders often select triple clamps based on their need for either increased flex and comfort or enhanced front-end stiffness and precision.

Key Differences

Forged vs Billet Overview

Motorcycle triple clamps come in two main types: forged and billet. Each type uses a distinct manufacturing process, which leads to differences in structure, weight, and performance. The table below highlights the primary distinctions:

Aspect | Forged Triple Clamps | Billet Triple Clamps |

|---|---|---|

Manufacturing Process | Shaped under extremely high pressure from aluminum ingots | Machined from a single solid block of high-grade aluminum |

Denser, more randomly intertwined grain structure | Denser, more uniform grain structure with fewer weak points | |

Material Used | Typically 6000-series Kinesium alloy | High-grade aluminum block |

Strength | Stronger due to grain structure but heavier | Offers unmatched strength and durability due to uniformity |

Weight | Heavier due to forging process | Lighter compared to forged clamps |

Machining | CNC machined after forging to remove excess material | Precisely CNC machined for superior finish and precision |

Durability | Proven strength over race testing | Better resistance to cracks and breakage |

Finish Quality | Factory-like finish after machining | Premium, precise machining with customizable appearance |

Billet triple clamps stand out for their precise machining and customizable finishes. Forged triple clamps, however, offer a robust grain structure that enhances strength and reliability.

Why Manufacturing Matters

The way manufacturers produce triple clamps directly affects their mechanical properties. Forging applies intense pressure to heated aluminum, refining the grain flow and improving tensile strength, fatigue resistance, and impact toughness. This process eliminates internal voids, resulting in components with superior uniformity and reliability. Billet clamps, while machined from high-quality aluminum, do not undergo grain refinement during production. As a result, forged triple clamps generally provide greater toughness and fatigue resistance.

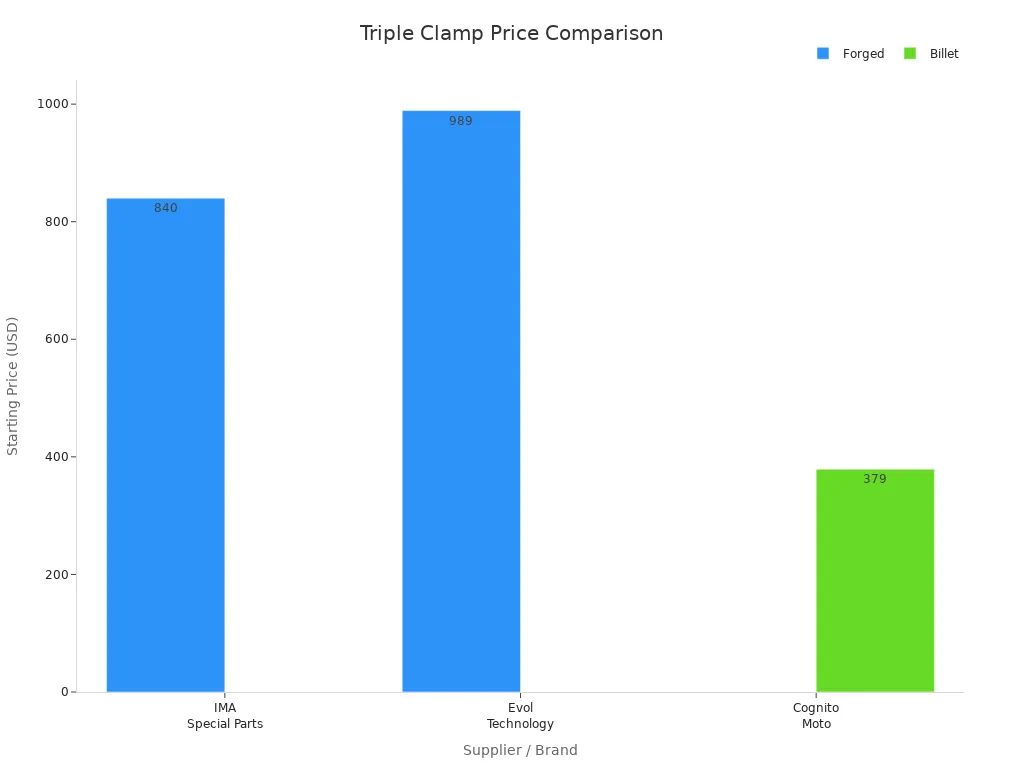

Cost also plays a role in the decision-making process. The chart below compares starting prices for forged and billet triple clamps from major suppliers:

Billet triple clamps often start at a lower price point, but customization and premium finishes can raise costs to match or exceed those of forged options. Riders should consider both performance needs and budget when selecting the right triple clamps for their motorcycle.

Triple Clamps Function

Steering and Handling

Triple clamps serve as the backbone of a motorcycle’s front end. They connect the front forks to the frame and provide mounting points for handlebars and accessories. Their design and construction directly influence how a motorcycle steers and handles. Key roles include:

Connecting the front forks to the motorcycle frame and setting the fork offset, which determines the rake and trail.

Maintaining structural integrity and rigidity of the front end, which affects vibration damping and overall handling.

Distributing forces during riding, which shapes the motorcycle’s handling characteristics.

Allowing for adjustments in steering geometry through adjustable designs, enabling riders to fine-tune handling.

Influencing front-end rigidity and flex through material choice and thickness, which balances durability and rider feedback.

Offset, rake, and trail are critical geometry factors set by the triple clamp fork. Adjusting the offset changes the rake and trail, which modifies how quickly the motorcycle leans and its stability during turns. Increased trail improves high-speed stability but can slow down turning response. Thinner triple clamps flex more, transmitting greater road feel, while thicker clamps increase rigidity but may reduce feedback.

Tip: Riders seeking a personalized feel often choose adjustable triple clamps to modify fork tube positioning and tailor handling to their preferences.

Suspension and Comfort

Engineering analyses show that triple clamps play a vital role in suspension performance and rider comfort. These components endure dynamic loads and unwanted vibrations from road irregularities. Such vibrations can cause significant hand and arm discomfort for riders. Achieving both high stiffness and high damping presents a challenge, as these qualities often conflict. Recent innovations, such as integrating particle damping through advanced manufacturing, have enhanced both stiffness and damping. Experimental studies reveal that damping can increase by up to 20 times, significantly reducing vibration transmission. This improvement not only boosts suspension performance but also enhances comfort by minimizing harmful vibrations. Optimized triple clamp design can also reduce mass and integrate additional functions, further benefiting motorcycle dynamics and rider experience.

Forging Motorcycle Triple Clamp Process

Forging Steps

The forging motorcycle triple clamp process transforms raw aluminum into a high-performance component. Manufacturers follow a series of precise steps to ensure maximum strength and reliability:

Material Selection: Engineers choose 6061-T6 aluminum alloy for its excellent strength, corrosion resistance, and machinability.

Heating: The aluminum reaches temperatures near 800°C, making it soft and malleable for shaping.

Pre-Forming: Workers place the heated aluminum into a die, shaping it roughly like a triple clamp.

Forging: A powerful press applies immense pressure, forcing the aluminum into its final triple clamp shape. This step refines the grain structure and increases density.

Heat Treatment: The forged part undergoes controlled heating and rapid cooling, which boosts hardness and durability.

Machining: Technicians finish the forging motorcycle triple clamp by adding mounting holes and other features.

Each step in the forging motorcycle triple clamp process enhances the material’s properties. The combination of heat, pressure, and alloy selection produces a component that stands up to the demands of motorcycle riding.

Note: The forging motorcycle triple clamp process creates a denser, more uniform grain structure, which improves both strength and fatigue resistance compared to other manufacturing methods.

Strength and Flex

The forging motorcycle triple clamp process gives the finished product unique mechanical advantages:

The grain structure in forged aluminum aligns with the shape of the triple clamp, improving load distribution and fatigue resistance.

Forged clamps typically show higher tensile strength (400-550 MPa) and yield strength (350-500 MPa) than billet clamps.

Directional grain alignment allows forged triple clamps to flex slightly under stress, which increases comfort and reduces vibration for the rider.

The forging motorcycle triple clamp process results in a lighter and more durable component, making it ideal for high-stress applications.

Forged triple clamps excel in durability and rider comfort. Their ability to flex without sacrificing strength sets them apart from other options.

Billet Triple Clamps Process

CNC Machining Steps

Billet triple clamps begin as solid blocks of high-grade aluminum. Engineers use advanced CNC machining centers to transform these blocks into precision components. The process involves several specialized machines, each contributing to the final product’s quality. The table below outlines the main stages and their effects:

Stage | Description | Effect on Final Product Quality |

|---|---|---|

CNC Machining Center | Performs drilling, lathe, and milling operations in one versatile machine. | Enables complex shapes and flexible processing, improving precision and accuracy. |

CNC Lathe | Produces round shapes with accurate inner and outer diameters. | Ensures precise circular features critical for fit and function. |

Precision Cutting Machine | Used for workpieces requiring tight tolerances and accurate measurements at various angles. | Achieves high dimensional accuracy and tight tolerances. |

CNC Milling Machine | Removes material by cutting away from the workpiece (subtractive manufacturing). | Allows detailed shaping and finishing, enhancing surface quality and dimensional control. |

Engineers rely on automation throughout the production of cnc-machined clamps. This approach reduces human error and increases consistency. The use of advanced machinery also speeds up production, allowing manufacturers to deliver bulk orders efficiently. Each billet triple clamp receives careful attention to detail, resulting in a product with superior fit and finish.

Tip: CNC-machined clamps offer unmatched repeatability, making them ideal for riders who demand consistent performance across multiple bikes.

Rigidity and Precision

Billet triple clamps stand out for their exceptional rigidity and precise steering feel. The CNC machining process removes unnecessary material while maintaining structural integrity. Engineers use topology optimization and finite element analysis to refine the design, ensuring the clamp remains lightweight without sacrificing strength. This engineering-driven approach produces a triple clamp that delivers a more direct connection between the rider and the road.

Stiffer billet triple clamps provide a more rigid front end, which improves steering accuracy and feedback. Riders experience less flex under load, resulting in sharper handling and increased confidence at high speeds. The precise tolerances achieved during CNC machining ensure that every clamp fits perfectly, enhancing both safety and performance.

Manufacturers design cnc-machined clamps to meet the demands of competitive racing and aggressive street riding. The combination of advanced engineering and meticulous manufacturing creates a product that excels in both durability and rider comfort.

Performance Comparison

Strength and Durability

Manufacturers design triple clamps to withstand intense forces during aggressive riding. Forged triple clamps rely on a dense grain structure created by high-pressure shaping. This process delivers reliable strength and fatigue resistance, making them suitable for demanding environments. Billet triple clamps, especially those produced by CNC machining with topology optimization, often achieve nearly twice the strength of some forged models. Engineers remove unnecessary material and reinforce critical areas, resulting in clamps that resist cracking and deformation under stress.

The following table highlights key differences in strength and durability between forged and billet triple clamps:

Aspect | Forged (Stock) Triple Clamps | Billet (Luxon MX CNC Machined) Triple Clamps |

|---|---|---|

Cast or forged with design constraints for casting/forging | CNC machined with topology optimization, no casting constraints | |

Strength | Adequate but limited by manufacturing process | Nearly twice as strong in some models (e.g., KTM/Husqvarna/GasGas) |

Design Constraints | Driven by casting/forging requirements (flat tops, ribs for metal flow) | Freeform design with thru holes, variable wall thickness, angled ribs |

Billet triple clamps benefit from advanced engineering and fewer design limitations. Riders who prioritize maximum durability and reliability often choose billet options for their motorcycles.

Weight and Flex

Weight and flex characteristics play a significant role in motorcycle handling and rider comfort. Forged triple clamps tend to be heavier due to manufacturing limitations. The forging process requires thicker sections and additional ribs to maintain strength, which adds mass. Billet triple clamps, such as those from Luxon MX, use CNC machining to remove excess material and optimize wall thickness. This approach produces lighter clamps that reduce overall bike weight and improve maneuverability.

Flex characteristics also differ between the two types. Forged triple clamps usually offer less controlled flex, which can result in a stiffer front-to-back feel. Billet triple clamps allow engineers to tailor flex properties for specific models. For example, some billet clamps increase longitudinal flex to enhance rider comfort while maintaining high torsional stiffness for precise steering.

Aspect | Forged (Stock) Triple Clamps | Billet (Luxon MX CNC Machined) Triple Clamps |

|---|---|---|

Weight | Heavier due to manufacturing limitations | Lighter due to optimized material removal and design |

Stiffness in Torsion | Generally less optimized; varies by model | Increased torsional stiffness for precise steering (e.g., KTM/Husqvarna/GasGas) |

Longitudinal Flex | Less controlled, often stiffer front-to-back | More flex longitudinally for rider comfort (e.g., KTM/Husqvarna/GasGas) |

Model-Specific Notes | Yamaha clamps are stiff but heavy and less comfortable | Yamaha billet clamps maintain torsional stiffness, increase comfort, and reduce weight by ~0.5 lb |

Lighter triple clamps contribute to quicker handling and reduced rider fatigue. Optimized flex characteristics help balance comfort and performance, especially during long rides or competitive events.

Rider Feel

Rider feedback remains a critical factor in triple clamp selection. Professional riders have shared mixed opinions about the feel of forged versus billet triple clamps during competitive riding:

Some riders noticed a harsh front-end feel with early billet triple clamps, prompting engineers to modify designs by beveling and rounding edges.

Factory teams often experiment with swapping billet clamps for forged cast clamps, seeking the ideal balance between stiffness and comfort.

Several riders claim to feel distinct differences between forged and billet clamps, especially after design changes, while others believe the differences are subtle or psychological.

Engineers point out that measurable clamp deflection is extremely small compared to overall bike dynamics, raising questions about whether riders can truly perceive these changes.

Rider feedback remains essential; even perceived differences can impact confidence and performance, leading teams to prioritize rider satisfaction.

The consensus among professionals is mixed. Some report feeling differences, others do not, but all agree that the feel of triple clamps affects rider satisfaction and potentially performance.

Note: Teams value rider happiness and confidence, even when the technical differences between forged and billet triple clamps are minimal. The psychological impact of equipment choice can influence lap times and overall results.

Comfort and Handling

Vibration and Feedback

Triple clamps play a crucial role in how a motorcycle transmits vibration and feedback to the rider. Forged aluminum triple clamps stand out for their superior flex characteristics. This design allows the clamp to absorb and transmit vibrations in a way that many riders find more comfortable. Riders often report that forged clamps provide better feedback through the handlebars, which can enhance confidence during aggressive riding. The flex in forged clamps reduces distortion when clamping the fork tubes, resulting in a more consistent feel. Although these observations come from rider experiences rather than instrumented testing, many professionals trust the improved feedback offered by forged designs.

Billet triple clamps, on the other hand, deliver a stiffer and more direct connection between the front end and the rider. The increased rigidity can sharpen steering response and provide a more precise feel. However, some riders may notice more vibration transmitted through the handlebars, especially on rough surfaces. The choice between forged and billet clamps often comes down to personal preference and the type of riding. Riders who prioritize comfort and subtle feedback may prefer forged clamps, while those seeking maximum precision often select billet options.

Tip: Riders should consider their sensitivity to vibration and the type of terrain they most frequently encounter when choosing between forged and billet triple clamps.

High-Speed Stability

High-speed stability remains a top priority for both street and track riders. Triple clamp design directly influences how stable a motorcycle feels during acceleration, braking, and cornering. Aftermarket triple clamps, whether forged or billet, often improve handling by increasing steering precision and front-end stability. These upgrades can reduce wobbling or “tank slappers” at high speeds.

Aftermarket triple clamps allow riders to fine-tune ergonomics and handling through adjustable fork offset and handlebar position.

High-quality materials, such as aluminum, increase durability and reduce unsprung weight, which improves responsiveness.

Proper installation is essential; incorrect setup can compromise handling and safety.

Compatibility with the motorcycle model ensures optimal performance and fit.

Adjustable triple clamps give riders the ability to increase trail, which enhances straight-line stability but may slow down steering response. Upgraded triple clamps provide better stability on paved surfaces, especially at higher speeds. While suspension setup, tire choice, and rider skill also affect performance, the design and quality of the triple clamp play a significant role in maintaining control and confidence at speed.

Note: Riders should always verify compatibility and follow manufacturer guidelines during installation to maximize the benefits of upgraded triple clamps.

Real-World Use

Street Riding

Street motorcycles rely on triple clamps for both comfort and control. Manufacturers such as Yamaha, Honda, and Suzuki often use forged aluminum clamps in their stock models. These provide a balance of flex and comfort, which helps absorb road imperfections and reduces rider fatigue. KTM and Husqvarna equip some street bikes with CNC-machined clamps, offering increased rider feedback and sharper cornering. The GasGas SM 700, for example, features CNC-machined triple clamps that balance flex and feedback, while rubber-mounted bar clamps reduce vibration for added comfort.

Triple Clamp Type | Material/Process | Common Manufacturers (Stock) | Performance Characteristics |

|---|---|---|---|

Forged Aluminum | Forged aluminum billet | Yamaha, Honda, Kawasaki, Suzuki, GasGas | More flex and comfort; beneficial for daily riding |

CNC-Machined | CNC-machined from billet | KTM, Husqvarna, aftermarket clamps | Enhanced feedback and cornering accuracy |

Split Triple Clamps | Split clamp design | Aftermarket, specialized uses | Even grip on fork legs, less fork binding, improved feel |

Offset Variations | Design geometry | Various | Less offset sharpens turning; more offset increases stability |

Riders who commute or tour often prefer forged clamps for their comfort. Those seeking a sportier feel may choose billet or split designs for improved precision.

Track and Racing

Track and racing environments demand maximum performance from triple clamps. Race teams use both custom forged and billet clamps to reduce front-end flex and fine-tune geometry. These upgrades deliver several advantages:

Improved handling precision and turn-in response

Enhanced high-speed stability

Lighter, stronger components that boost power-to-weight ratio

Adjustable trail, rake, and rider geometry for better balance and agility

Small geometry tweaks for significant gains in cornering and stability

CNC-Bearbeitung allows engineers to tailor each clamp for specific racing needs. Riders benefit from sharper steering and greater control, especially during aggressive maneuvers.

Off-Road

Off-road riders face unique challenges, including rough terrain and unpredictable impacts. Forged triple clamps excel in these conditions by providing controlled flex, which absorbs shocks and reduces rider fatigue. Many motocross and enduro bikes use forged clamps for their durability and comfort. However, some high-end off-road models feature billet clamps, which offer increased rigidity and precise steering. Riders who compete in demanding events may prefer billet clamps for their strength and ability to maintain alignment under stress. The choice depends on the rider’s preference for comfort versus precision and the specific demands of the terrain.

Tip: Off-road riders should match their triple clamp choice to their riding style and the typical conditions they encounter.

Pros and Cons

Forged Clamps

Forged triple clamps offer several advantages for riders who prioritize durability and comfort. Manufacturers use a forging process that aligns the grain structure of aluminum, resulting in components with high fatigue resistance. Riders benefit from increased flex, which absorbs road vibrations and reduces hand fatigue during long rides. This flex also provides a more forgiving feel on rough terrain, making forged triple clamps popular among off-road and street riders.

However, forged triple clamps tend to be heavier than billet alternatives. The manufacturing process requires thicker sections to maintain strength, which can add weight to the motorcycle’s front end. Some riders may notice less steering precision compared to billet clamps, especially during aggressive cornering. The finish quality, while robust, may lack the premium appearance of CNC-machined options.

Note: Forged triple clamps excel in environments where comfort and reliability matter most, but may not deliver the sharpest steering response for competitive racing.

Billet Clamps

Billet triple clamps stand out for their precision and adjustability. Manufacturers use CNC machining to create clamps with tight tolerances and customizable finishes. Riders experience improved steering accuracy and front-end bite, especially with models like Ride Engineering’s, which provide razor-sharp turn-in. The split pinch bolt design and rubber-cushioned bar mounts found on some billet clamps, such as Xtrig ROCS Pro, enhance comfort by reducing unwanted rigidity and vibration.

Aspect | Pros | Cons |

|---|---|---|

Steering Precision | Razor-sharp turn-in and improved accuracy. | Slight flex possible if bolts are not torqued correctly. |

Comfort | Balanced flex absorbs bumps better than some stock clamps. | Some riders prefer stiffer settings; intermediate riders noted slight flex. |

Vibration Dampening | Rubber mounts reduce vibration. | Additional kits required for some models. |

Material & Build | High-quality CNC-machined billet aluminum. | Higher cost compared to forged clamps. |

Handling Trade-offs | Compromise between rigidity and flex for better cornering. | No significant complaints in technical tests. |

Xtrig ROCS Pro clamps offer six handlebar mount positions and elastomer bumpers for vibration dampening.

The PDHS system prevents handlebar twisting and allows customization of vibration absorption.

Installation remains straightforward despite multiple adjustment features.

Billet triple clamps improve comfort and handling, but price points often exceed $700.

Tip: Riders seeking maximum adjustability and steering precision often choose billet triple clamps, accepting higher costs for premium features.

Choosing Triple Clamps

Rider Needs

Selecting the right triple clamp depends on the rider’s style, comfort preferences, and performance goals. Riders should first identify their primary use case. Street riders often value comfort and reduced vibration. Off-road enthusiasts need durability and controlled flex to handle rough terrain. Track and racing riders demand maximum precision and rigidity for aggressive cornering.

Key factors to consider include:

Riding Style: Commuters and touring riders benefit from comfort-focused clamps. Racers and sport riders require precise steering.

Terrain: Off-road conditions call for components that absorb shocks. Smooth pavement allows for stiffer, more responsive setups.

Bike Compatibility: Not all triple clamps fit every motorcycle. Riders must check manufacturer specifications before purchasing.

Adjustability: Some aftermarket triple clamps offer adjustable offset or handlebar positions, allowing riders to fine-tune handling.

Budget: High-end billet clamps often cost more than forged options. Riders should balance performance needs with available funds.

Tip: Riders who frequently switch between street and track may benefit from adjustable aftermarket triple clamps for greater versatility.

The key differences between forged and billet triple clamps appear in their manufacturing, performance, and typical usage. The table below summarizes these distinctions:

Aspect | Forged Triple Clamps | Billet (CNC-machined) Triple Clamps |

|---|---|---|

Manufacturing Process | Forged with hydraulic or mechanical presses | CNC-machined from solid aluminum billet |

Performance | More flex and comfort | Stiffer, more precise steering |

Usage | Common on Japanese stock bikes | Preferred for customization and racing |

Riders who value comfort and durability often select forged clamps. Those seeking sharper handling and customization choose billet options. Matching clamp type to riding style ensures the best performance and feel.

FAQ

What is the main advantage of billet triple clamps?

Billet triple clamps provide superior rigidity and precise steering. Riders often choose them for racing or aggressive street riding. The CNC machining process allows for custom finishes and tight tolerances.

Are forged triple clamps better for comfort?

Yes. Forged triple clamps offer more flex, which absorbs road vibrations and improves rider comfort. Many street and off-road riders prefer forged clamps for daily use and long rides.

Can you install billet triple clamps on any motorcycle?

Riders must check compatibility before purchasing. Not all billet triple clamps fit every motorcycle model. Manufacturers usually list supported bikes in product details.

Do billet triple clamps require special maintenance?

No special maintenance is needed. Riders should inspect all triple clamps regularly for signs of wear or damage. Proper torque on bolts ensures safety and performance.