Why die cast aluminum cannot be anodized

Die cast aluminum cannot be effectively anodized. The alloy contains high silicon and other elements that interrupt the anodizing process. Porosity from casting introduces voids, which prevent the formation of a consistent anodic layer. These issues make casting anodized surfaces unreliable. Manufacturers often choose alternative finishes to achieve durable protection.

Main Reasons Die Cast Aluminum Can’t Be Anodized

Alloying Elements

Die cast aluminum alloys contain a mix of elements such as silicon, copper, iron, and manganese. Each element changes the way the metal reacts during the anodizing process. Copper and zinc, for example, do not respond well to the electrolytic baths used in anodizing. These elements can cause the oxide film to appear red or yellow, degrade the quality of the electrolyte, and increase oxidation defects. Silicon, when present in high amounts, leads to a gray oxide film and black spots after anodizing.

Silicon leads to an uneven surface response during anodization, forming silicon dioxide, which is commonly known as quartz. Additionally, copper and zinc in cast aluminum alloys react poorly with the electrolytic baths used in the anodizing process.

Manufacturers often choose die cast alloys for their strength and castability, but these same properties make casting anodized finishes unreliable. The presence of copper results in a hard and strong material, but it also creates an unattractive yellow oxide layer when anodized. Magnesium alloys, on the other hand, show better anodizing characteristics and do not negatively affect the anodized film quality.

Copper can cause the oxide film to appear red, degrade the quality of the electrolyte, and increase oxidation defects.

Silicon can lead to a gray oxide film, especially when its content exceeds 4.5%, resulting in black spots after anodization.

Common alloying elements in die cast aluminum alloys include iron, copper, silicon, and manganese. Iron helps counteract metallization and enhances mold life, but it can also affect anodizing due to intermetallics. Copper contributes to internal cracks and porosity in the anodized layer. Silicon improves castability but limits oxide thickness and promotes defects. Manganese enhances mechanical properties and mitigates the negative effects of iron.

High Silicon Content

Silicon is the most significant alloying element in die cast aluminum. Its content in die cast alloys is much higher than in alloys suitable for anodizing. High silicon content changes the way the aluminum and silicon phases conduct electricity, which affects the oxide growth rate and the development of coatings. This makes it difficult to achieve thick, dense, and homogeneous anodic coatings, especially in advanced processes like Plasma Electrolytic Oxidation (PEO).

Alloy Type | Silicon Content (%) | Anodizing Suitability |

|---|---|---|

Die Cast Aluminum Alloys | 10.5 – 13.5 | Not suitable for anodizing (high silicon) |

Alloys Suitable for Anodizing | < 7 | Ideal for anodizing (low silicon) |

High silicon content leads to poor appearance in casting anodized finishes. The surface may look brownish gray or black, sometimes with a ‘sooty’ appearance. The anodic coating may not be dense or continuous, which causes failures in salt spray tests. These problems make casting anodized surfaces less reliable for corrosion protection and appearance.

Porosity Issues

The die casting process introduces porosity into the aluminum part. Gas trapped during casting creates tiny holes or voids in the metal. These voids become more visible after anodizing and affect the uniformity and adhesion of the anodic coating. Certain alloying elements can also contribute to gas porosity, making the problem worse. If the casting parameters are not controlled properly, more gas gets trapped, leading to increased porosity.

Gas trapped during casting leads to porosity, which becomes more visible after anodizing.

Alloy composition can contribute to gas porosity, affecting the anodizing outcome.

Improper casting parameters result in gas entrapment, impacting anodic coating uniformity and adhesion.

Porosity prevents the formation of a continuous anodic layer. The anodic film may peel off or show uneven thickness, which reduces the protective qualities of casting anodized surfaces. Manufacturers often report that high silicon alloys do not anodize well, resulting in a blotchy finish and diminished corrosion resistance.

Non-Uniform Anodic Film

Die cast aluminum surfaces show non-uniform anodic films due to variations in surface topography and microstructural differences. Surface irregularities, such as burrs and machining marks, create sites for charge concentration. These sites inhibit the formation of a consistent anodic layer. The rougher diecast surface, often caused by a worn die, leads to a more inhomogeneous anodic layer compared to the smoother milled surface. A greater eutectic fraction on the diecast surface further hinders the growth of the anodic layer.

Effect | Description |

|---|---|

Corrosion Resistance | Non-uniform anodic films lead to reduced integrity and strength, affecting resistance. |

Appearance | Results in a dull or gray finish, especially in high copper alloys. |

Abrasion Resistance | Poor abrasion resistance due to the integrity loss of the anodized film. |

Localized Discoloration | Indicates improper alloying and processing, leading to aesthetic issues. |

Alloying Effects | High concentrations of alloying elements can cause a mat or gray appearance. |

The non-uniformity of the anodic film affects both the corrosion resistance and the appearance of casting anodized parts. The finish may look dull or gray, and the protective layer may not last as long. Manufacturers face challenges such as blotchy finishes, reduced corrosion resistance, and increased costs due to the need for multiple trials with non-standard anodizing baths.

Research studies show that the microstructure of die cast aluminum, especially the high eutectic silicon content and intermetallic compounds, leads to lower quality anodic films. Surface defects and the shape of silicon particles also change the growth and composition of the anodic film. A greater amount of the α-Al phase promotes thicker anodic layers, but die cast alloys usually have less of this phase.

Casting anodized finishes on die cast aluminum parts remain unreliable due to these technical barriers. The combination of alloying elements, high silicon content, porosity, and non-uniform anodic films explains why manufacturers prefer alternative surface treatments for die cast components.

Casting Anodized vs. Pure Aluminum

Alloy Comparison

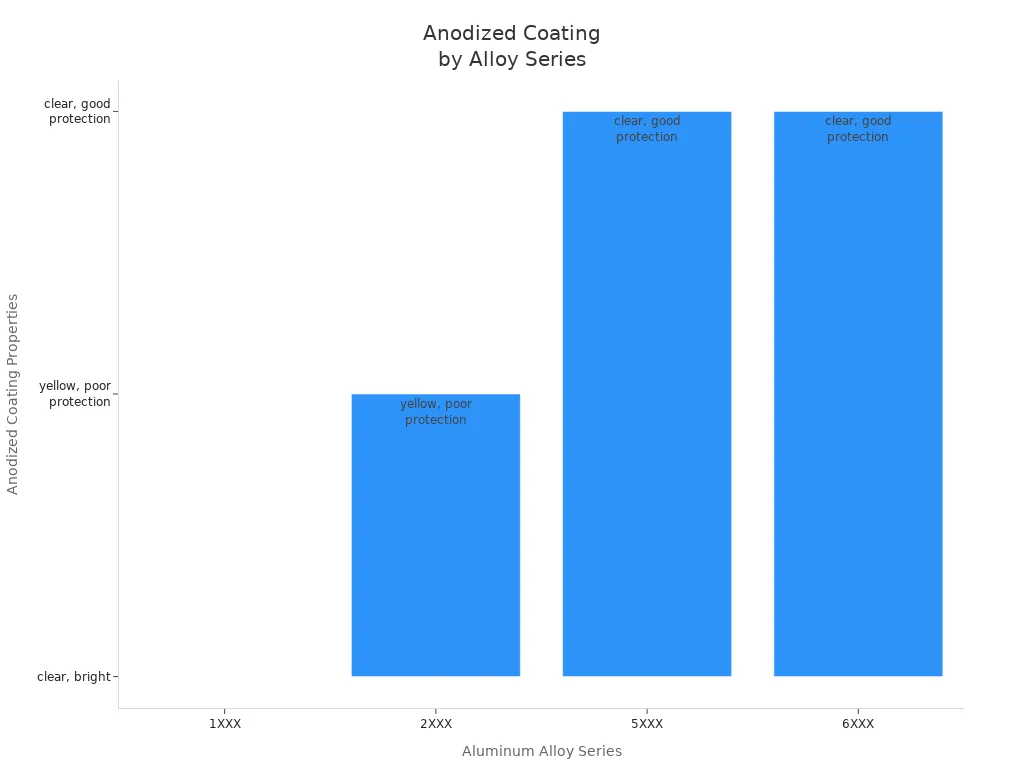

When comparing die cast aluminum, pure aluminum, and forged aluminum alloys, the differences in anodizing results become clear.

Pure aluminum produces a uniform and high-quality oxide layer during anodizing. The surface appears bright and consistent.

Die cast aluminum alloys contain higher levels of silicon and other elements. These impurities lead to inferior anodized finishes. The oxide film often looks dark or non-transparent.

Alloying elements such as copper and silicon can change the color of the anodized film. Silicon causes gray tones, while copper can create reddish hues.

Forged aluminum alloys, like pure aluminum, usually have fewer impurities. They respond well to anodizing, forming a dense and even oxide layer.

Alloy Type | Anodizing Quality | Typical Color | Common Defects |

|---|---|---|---|

Pure Aluminum | Excellent, uniform | Clear/Silver | Minimal |

Die Cast Aluminum | Poor, non-uniform | Gray/Dark | Porosity, color variation |

Forged Aluminum | Good, consistent | Silver/Gray | Few, mostly minor |

Pure aluminum and forged aluminum alloys are preferred for anodizing because they create a more reliable and attractive finish. Die cast alloys, especially those used for casting anodized parts, often fail to meet appearance and durability standards.

Surface Quality

Surface quality after anodizing depends on the alloy and manufacturing process.

Anodized die cast aluminum can achieve higher surface hardness, sometimes reaching HV300. This is much higher than the hardness of cast aluminum at HV100.

The corrosion resistance of anodized die cast aluminum improves compared to untreated surfaces. However, high silicon content and porosity often cause non-uniform oxide layers and surface defects.

Anodized pure aluminum offers better corrosion resistance and a more uniform, thicker oxide film. The finish is usually brighter and more consistent.

Forged aluminum alloys also provide a smooth, defect-free anodized surface. They resist corrosion and maintain color stability.

Most industries prefer pure or forged aluminum for applications that require anodizing. These include automotive, aerospace, and marine components. Die cast aluminum is rarely used for casting anodized finishes in these fields because its high silicon content and porosity reduce the quality and reliability of the anodized layer.

Surface defects, such as dark spots and uneven color, appear more often in casting anodized die cast aluminum. Pure and forged aluminum alloys avoid these problems, making them the top choice for high-performance anodized parts.

Alternatives to Anodizing Die Cast Aluminum

Process Engineering Changes

Engineers have explored several process changes to improve the anodizing results of die cast aluminum. Adjusting the casting method can influence the hardness and quality of the anodized layer. High-pressure casting, for example, increases the hardness of anodized parts by up to 46%. Sand casting, however, shows only a negligible change in hardness after anodizing. The table below highlights these differences:

Casting Method | Non-Anodized Hardness (HRF) | Anodized Hardness (HRF) | Hardness Increase (%) |

|---|---|---|---|

High-Pressure Casting | 9.51 | 13.96 | 46% |

Sand Casting | 10.14 | 11.43 | Negligible Change |

Despite these improvements, process engineering changes cannot fully overcome the fundamental issues caused by high silicon content and porosity. The anodized layer remains inconsistent, and the surface often fails to meet appearance or durability standards. Manufacturers continue to seek better alternatives for protecting die cast aluminum parts.

Other Surface Treatments

Many industries turn to alternative surface treatments when anodizing does not deliver the desired results for die cast aluminum. Each method offers unique benefits and drawbacks:

Surface Treatment | Corrosion Resistance | Wear Resistance | Aesthetic Appeal | Cost-Effectiveness |

|---|---|---|---|---|

E-coating | Better | Moderate | Smooth finish | Cost-effective |

Anodizing | Good | High | Can exaggerate flaws | More expensive |

Powder Coating | Good | Moderate | Decorative finish | Moderate |

Alodine Finish | Improved | Low | N/A | Cheaper than anodizing |

E-coating provides uniform coverage and superior corrosion protection.

Powder coating creates a decorative and protective layer, though it may not match anodizing for durability.

Alodine finish improves corrosion resistance but offers less wear protection.

Additional options include bead blasting, electroplating, polishing, and brushing.

Cost also plays a role in selecting a surface treatment. Chromate conversion coatings range from $0.03 to $0.08 per cm², while clear coatings cost between $0.10 and $0.25 per cm². These alternatives often prove more affordable than color anodizing, which can reach up to $2.00 per square inch.

Manufacturers choose these alternatives because they address the limitations of anodizing die cast aluminum. They provide better protection, improved appearance, and lower costs for many applications.

Die cast aluminum cannot be anodized effectively because its alloy composition and casting process introduce several barriers:

Porosity from casting creates voids that weaken the coating.

A low aluminum-to-other-metals ratio leads to surface defects.

Manufacturers can improve corrosion resistance by following these steps:

Apply specialized coatings to die cast parts.

Inspect coatings regularly and monitor environmental conditions.

Use strict quality control to ensure consistent performance.

FAQ

Why does high silicon content prevent effective anodizing of die cast aluminum?

High silicon content interrupts the formation of a uniform oxide layer. Silicon does not anodize like aluminum. This leads to patchy, gray, or black surfaces. The result is a weak and unattractive anodic coating.

Why do manufacturers avoid anodizing die cast aluminum parts?

Manufacturers avoid anodizing die cast aluminum because the process produces inconsistent results. Porosity and alloying elements cause poor adhesion and uneven color. The finished parts often fail to meet appearance and durability standards.

Why does porosity from die casting affect anodizing quality?

Porosity introduces tiny holes and voids in the metal. These defects disrupt the anodizing process. The anodic film forms unevenly, which weakens corrosion resistance and creates a blotchy appearance.

Why do alternative surface treatments work better for die cast aluminum?

Alternative treatments like powder coating or e-coating cover surface defects and provide better protection. These methods do not rely on the alloy’s composition. They create a more uniform and attractive finish.

Why is pure aluminum preferred for anodizing over die cast alloys?

Pure aluminum contains fewer impurities and less silicon. The anodizing process forms a thick, clear, and durable oxide layer. This results in a consistent appearance and strong corrosion resistance.