Aluminum Hot Forging vs Cold Forging Pros and Cons Explained

Aluminum hot forging and cold forging each present distinct advantages and disadvantages. Many manufacturers rely on aluminum hot forging for superior malleability and improved mechanical properties, while cold forging is preferred for greater accuracy and a finer surface finish. The table below outlines the main differences:

Forging Method | Advantages | Disadvantages |

|---|---|---|

Cold Forging | Improved accuracy, Enhanced surface finish, Raw material savings | Higher costs, Limited material suitability, Risk of brittleness |

Hot Forging | Superior malleability, Reduced strain hardening, Enhanced mechanical properties | Metal surface reaction, Dimensional inaccuracy, Shorter tool life, Requires specialized equipment and skilled workers |

Choosing the appropriate process depends on the specific application, such as forging automotive parts, forging bicycle parts, or forging e-scooter parts. Every forging company must evaluate factors like material, cost, and performance. An aluminum forging company can provide expert guidance to ensure the selected method aligns with project requirements.

Quick Comparison

Main Pros and Cons

Aluminum forging uses two main approaches: hot forging and cold forging. Each method shapes aluminum by squeezing it between a punch and a die, but the temperature and process steps differ. Hot forging heats the metal to around 250°C, while cold forging works at room temperature. These differences affect the properties and applications of the final product.

Hot forging improves the yield strength and ductility of aluminum. The high temperature allows the metal to flow easily, which helps create complex shapes and refines the grain structure. Manufacturers often choose hot forging for parts that need toughness and intricate designs. However, hot forging can lead to dimensional inaccuracies and requires specialized equipment.

Cold forging increases the strength of aluminum through hardening. This method produces parts with high concentricity and close tolerances. Cold forging works best for high-strength alloys and simple shapes. The process often needs intermediate soft annealing and lubrication for complex geometries. Cold forging saves raw material and provides a smooth surface finish, but it limits the complexity of shapes and may cause brittleness.

Key differences in process parameters include temperature, material behavior, and production efficiency. Hot forging usually needs fewer operations, making it more economical for complex parts. Cold forging often takes more time due to multiple steps.

Comparison Table

Feature/Parameter | Hot Forging | Cold Forging |

|---|---|---|

Temperature | ~250°C | Room temperature |

Material Behavior | Flows easily, less need for intermediate steps | Needs soft annealing, lubrication for complex shapes |

Production Efficiency | Fewer operations, more economical | Multiple operations, time-consuming |

Shape Complexity | Suitable for complex shapes | Best for simple shapes |

Mechanical Properties | Enhanced yield strength, ductility | Increased strength, limited ductility |

Surface Finish | May require post-processing | Smooth, precise finish |

Raw Material Savings | Moderate | High |

Risk Factors | Dimensional inaccuracy, warping | Brittleness, cracking |

Tooling Requirements | Specialized equipment, skilled workers | Standard equipment, less skill needed |

Cold forging is ideal for high-strength aluminum alloys that need close tolerances.

Hot forging allows manufacturers to produce complex geometries with fewer steps.

Hot forging enhances toughness and grain structure, while cold forging improves accuracy and surface quality.

This quick comparison helps manufacturers and engineers select the right forging method based on the needs of their project. Each process offers unique benefits and challenges, so understanding these differences leads to better material selection and manufacturing outcomes.

Aluminum Hot Forging Overview

Process Steps

Aluminum hot forging transforms raw aluminum into strong, durable parts through a series of controlled steps. The process follows strict manufacturing standards to ensure quality and consistency. Here is a typical sequence:

Material Selection: Engineers choose the right aluminum alloy based on the required strength, ductility, and application.

Mold Design: Designers create molds that match the exact specifications of the final part.

Heating: Workers heat the aluminum to around 250°C. This temperature makes the metal malleable and easier to shape.

Forja: The heated aluminum is placed into a die and pressed into shape using powerful equipment.

Cooling: The forged part cools slowly to prevent internal stresses, cracking, or warping.

Heat Treatment: Some parts undergo additional heat treatment to further improve strength and toughness.

Machining and Finishing: Technicians cut, drill, or finish the forged part to achieve precise dimensions and a smooth surface.

Surface Treatment: The final step often includes treatments to enhance corrosion resistance and improve appearance.

Key Features

Aluminum hot forging offers several important features that make it a popular choice in manufacturing:

Enhanced Malleability: The high temperature allows aluminum to flow easily, making it possible to form complex shapes.

Improved Grain Structure: The forging process refines the grain structure, which increases the toughness and durability of the part.

Consistent Mechanical Properties: Parts produced by aluminum hot forging show uniform strength and ductility throughout.

Reduced Strain Hardening: The process minimizes the risk of the metal becoming brittle during shaping.

Versatility: Manufacturers can use aluminum hot forging for a wide range of part sizes and shapes.

These features help industries produce reliable components for demanding applications.

Common Alloys

Manufacturers select specific aluminum alloys for hot forging based on the desired properties of the finished part. Some of the most common alloys include:

Alloy Series | Typical Alloys | Key Properties | Common Uses |

|---|---|---|---|

2xxx | 2014, 2024 | High strength, good machinability | Aerospace, automotive |

6xxx | 6061, 6082 | Good formability, corrosion resistance | Bicycle parts, structural |

7xxx | 7075 | Very high strength, moderate toughness | High-performance equipment |

Each alloy responds differently to aluminum hot forging. For example, 6061 is popular for its balance of strength and corrosion resistance, while 7075 is chosen for applications that demand maximum strength.

Cold Forging Overview

Process Steps

Cold forging shapes aluminum at room temperature using high-pressure equipment. This process starts with selecting the right aluminum alloy. Workers cut the alloy into slugs or blanks. They then clean and lubricate the material to reduce friction and prevent sticking. The next step involves placing the blank into a die. A powerful press forces the aluminum into the desired shape. After forming, technicians may trim excess material and perform light finishing. Some parts require intermediate annealing to restore ductility before further shaping.

Key Features

Cold forging offers several important features that make it valuable for manufacturing aluminum parts:

High Dimensional Accuracy: This process produces parts with tight tolerances and consistent shapes.

Excellent Surface Finish: Cold forging creates smooth surfaces, which reduces the need for additional machining.

Material Efficiency: The process minimizes waste by using most of the starting material.

Enhanced Strength: Cold forging increases the strength of aluminum through work hardening.

Lower Energy Consumption: Since the process does not require heating, it uses less energy compared to hot forging.

Manufacturers often choose cold forging for parts that need high precision and strength. The process works best for simple shapes, such as shafts, bolts, and fasteners. Complex shapes may require additional steps or may not be suitable for cold forging.

Common Alloys

Not all aluminum alloys perform well in cold forging. Alloys with good ductility and moderate strength work best. The table below shows some common alloy series used in cold forging, along with their main alloying elements and typical applications:

Alloy Series | Alloying Element | Properties and Applications |

|---|---|---|

3xxx | Manganese | Moderate strength, used in beverage cans, heat exchangers, and cooking utensils. |

4xxx | Silicon | Excellent weldability, used in brazing alloys and automotive applications. |

5xxx | Magnesium | High strength and corrosion resistance, used in marine applications and construction projects. |

Alloys in the 3xxx series offer moderate strength and good formability, making them suitable for cold forging beverage cans and heat exchangers. The 4xxx series provides excellent weldability, which benefits automotive and brazing applications. The 5xxx series stands out for its high strength and corrosion resistance, making it ideal for marine and construction uses.

Manufacturers select the alloy based on the required properties of the finished part and the demands of the application.

Aluminum Hot Forging Pros and Cons

Advantages

Toughness

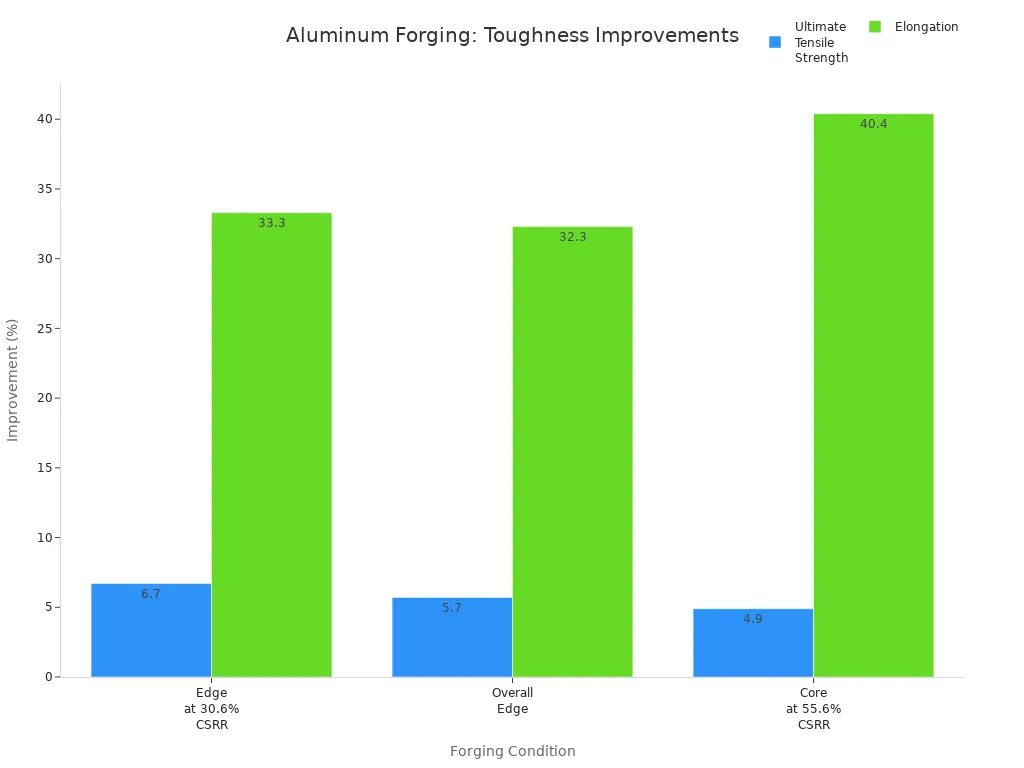

Hot forging gives aluminum parts a significant boost in toughness. When manufacturers use this process, they heat the metal and shape it while it is soft and ductile. This method helps the metal resist cracks and deformation during use. Scientific studies show that hot forging can increase the ultimate tensile strength of aluminum by up to 22%. Elongation, which measures how much a material can stretch before breaking, also improves by over 30%. These gains mean that forged aluminum parts can handle higher loads and impacts without failing.

Property | Value | Improvement (%) |

|---|---|---|

Tensile Strength | 454 MPa | 22 |

Yield Strength | 397 MPa | N/A |

Elongation | 11.8% | N/A |

The following chart shows how hot forging improves both tensile strength and elongation under different conditions:

These results highlight the improved toughness and material strength that hot forging brings to aluminum components. Engineers often choose this process for parts that must withstand heavy stress or impact.

Complex Shapes

Hot forging allows manufacturers to create complex shapes that would be difficult or impossible with other methods. The high temperature softens the aluminum, making it flow easily into detailed molds. This flexibility means designers can produce parts with intricate curves, thin sections, or unique geometries. Industries such as automotive and aerospace rely on hot forging to make components that need both strength and precise shapes. The process also reduces the number of machining steps, saving time and material.

Grain Structure

The grain structure of aluminum changes during hot forging. As the metal deforms at high temperatures, the grains become finer and more uniform. This process, called dynamic recrystallization, improves both strength and ductility. Fine grains help the metal resist cracks and fatigue, which increases the lifespan of the part.

Key Findings | Description |

|---|---|

Grain Refinement | The hot forging process leads to fine grain sizes, enhancing mechanical properties. |

Strength and Ductility | Fine grain sizes contribute to improved strength and ductility of aluminum alloys. |

Dynamic Recrystallization | This process regulates the microstructure and mechanical properties during hot deformation. |

During hot forging, aluminum alloys experience dynamic recovery and recrystallization.

Smaller initial grain sizes promote better recrystallization, which affects flow stresses and the final product’s characteristics.

These changes in grain structure give hot forged parts their well-known material strength and improved toughness.

Disadvantages

Warping Risk

Hot forging carries a risk of warping, especially during the cooling phase. Aluminum expands when heated and shrinks as it cools. If the cooling happens too quickly or unevenly, internal stresses can build up. These stresses may cause the part to warp or even crack. Warping is a common problem in bimetal components, where different metals cool at different rates. Sometimes, improper cooling can also create brittle phases in the metal, making it more likely to crack.

Warping and brittleness are significant risks during the cooling phase of hot forging.

Rapid or uneven cooling can lead to internal stresses, resulting in warping or cracking.

Aluminum’s high thermal expansion contributes to greater shrinkage during cooling, which can create gaps in bimetal components.

Improper cooling may form brittle intermetallic phases, weakening joints and increasing crack initiation risk.

Controlled cooling strategies can mitigate these risks.

Manufacturers must use careful cooling techniques to reduce these risks and ensure the quality of the final product.

Dimensional Accuracy

Hot forging can make it difficult to achieve precise dimensions. The high temperatures cause the metal to expand and contract, which can lead to slight changes in size and shape. As a result, parts may need extra machining or finishing to meet tight tolerances. This step adds time and cost to the production process. For applications that require exact measurements, cold forging or machining may offer better results.

Energy Use

Hot forging uses a large amount of energy. The process requires heating aluminum to temperatures as high as 530°C and holding it there for extended periods. Studies report that the mean energy consumption for hot-pressed aluminum AA6061 ranges from 25.10 to 53.92 kWh per kilogram. This high energy demand increases operational costs and environmental impact.

The mean energy consumption for hot-pressed aluminum AA6061 is between 25.10–53.92 kWh/kg.

The process involves heating to 530°C and holding at that temperature for over 80 minutes under high pressure.

Manufacturers must weigh these energy costs against the advantages of improved toughness and material strength when choosing hot forging for their projects.

Cold Forging Pros and Cons

Advantages

Surface Finish

Cold forging produces aluminum parts with a notably smooth surface. The process takes place at room temperature, which prevents the formation of scale or oxidation. As a result, the finished components often require little to no additional machining or polishing.

Cold forging results in a smoother surface due to the lack of scale or oxidation, which is often present in hot forging.

This benefit makes cold forging ideal for applications where appearance and surface quality matter, such as consumer electronics or visible automotive parts.

Precision

Manufacturers value cold forging for its ability to maintain tight tolerances. The process allows each part to retain its precise dimensions throughout production runs.

Cold forging maintains precise tolerances throughout production runs.

Cold-forged components are engineered to withstand substantial stress without reverting to their original form.

Although hot forging can create intricate features, cold forging excels in producing consistent, accurate parts. This precision reduces the need for secondary machining and ensures reliable performance in critical assemblies.

Material Savings

Cold forging stands out for its efficient use of raw materials. The process generates minimal waste and scrap, which leads to significant cost savings.

Cold forging can achieve material savings of up to 70% of production costs due to minimal waste and scrap.

This efficiency benefits manufacturers who seek to reduce expenses and environmental impact. Material savings also make cold forging attractive for high-volume production.

Strength and Ductility

Cold forging increases the strength of aluminum through work hardening. The process compresses the metal at room temperature, which aligns the grain structure and boosts mechanical properties. However, ductility decreases because the metal becomes less workable at lower temperatures.

Forging Type | Strength Outcome | Ductility Outcome | Additional Notes |

|---|---|---|---|

Cold Forging | Lower ductility due to low workability | High forging pressures reduce die life and shape complexity. | |

Hot Forging | Lower strength due to larger precipitates | Better ductility due to improved forgeability | May require final heat treatment for desired properties. |

Engineers often select cold forging when they need parts that can handle high stress without deforming.

Disadvantages

Shape Limitations

One of the main disadvantages of cold forging involves its limitations in forming complex shapes. The process works best for simple geometries, such as shafts, bolts, and fasteners. Complex designs may require multiple steps or may not be feasible at all. This restriction can limit the range of parts that manufacturers can produce using cold forging.

Forming Forces

Cold forging requires much higher forming forces compared to hot forging.

Cold forging operates at temperatures between 20°C to 40°C, requiring greater force to achieve the same deformation due to the material’s hardness.

Cold forging is performed at or near room temperature, typically necessitating higher forming forces due to the material’s increased strength at lower temperatures.

These high forces can increase equipment wear and energy consumption. Manufacturers must invest in robust machinery to handle these demands, which can raise initial setup costs.

Cracking Risk

Cracking represents another significant disadvantage of cold forging, especially with certain aluminum alloys.

Quench cracking in aluminum alloy 7010 can affect up to 80% of specific parts during the forging process.

Instances of cracking have been observed from both machined surfaces and surfaces within the forging prior to heat treatment.

The problem of quench cracking is intermittent and not widely reported in literature.

Cracking can compromise part integrity and lead to higher rejection rates. Manufacturers must carefully select alloys and control process parameters to minimize this risk.

Hot Forging vs Cold Forging: Applications

Typical Uses for Hot Forging

Hot forging plays a vital role in industries that demand strength and durability. Manufacturers often select this process for parts that must withstand high stress or complex loading conditions. The automotive and aerospace sectors rely heavily on hot forging to produce critical components.

In the automotive industry, hot forging creates engine components, suspension parts, wheels, structural elements, transmission components, electrical connectors, brake parts, universal joints, brake calipers, electric motor parts, and battery housings.

The aerospace industry uses hot forging for structural members, engine components, landing gear parts, wing fittings, and other high-stress elements.

Hot forging enables the production of parts with intricate shapes and refined grain structures. These qualities make it suitable for applications where safety and performance are essential. Many manufacturers choose hot forging when they need to balance toughness, reliability, and the ability to form complex geometries.

Typical Uses for Cold Forging

Cold forging excels in applications that require precision, smooth surfaces, and material efficiency. This process shapes aluminum at room temperature, which helps maintain tight tolerances and reduces waste. Electronics and consumer goods manufacturers often prefer cold forging for its ability to deliver high-quality finishes.

Casings for electronic devices benefit from cold forging, as do connectors used in various applications and heat sinks that improve thermal management.

Bicycle frames, golf clubs, and cookware also commonly use cold forging due to the process’s ability to create lightweight, strong, and visually appealing products.

Cold forging works best for simple shapes, such as shafts, bolts, and fasteners. The process supports high-volume production with consistent results. Manufacturers often select cold forging when they need to maximize material savings and achieve a refined appearance.

Industry Examples

Many industries depend on both hot forging and cold forging to meet specific needs. The automotive sector uses hot forging for safety-critical parts like suspension arms and brake calipers, while cold forging produces precision fasteners and connectors. Aerospace companies rely on hot forging for landing gear and wing fittings, ensuring strength under extreme conditions. Electronics manufacturers use cold forging to create device casings and heat sinks, which require excellent surface quality and thermal performance. Consumer goods, such as cookware and sports equipment, benefit from cold forging’s ability to produce lightweight and durable products.

A side-by-side approach to forging selection helps companies match the right process to each application. By understanding the strengths of hot forging and cold forging, manufacturers can optimize performance, cost, and quality across a wide range of industries.

Cost and Efficiency

Tooling and Setup

Tooling and setup play a major role in the overall cost of aluminum forging. Hot forging requires specialized dies and presses that can withstand high temperatures. These tools must resist thermal fatigue and frequent wear. Manufacturers often invest in advanced equipment and skilled workers to ensure reliable results. The initial cost for hot forging setup tends to be higher, especially for parts with complex shapes or tight precision requirements.

Cold forging uses standard equipment and simpler dies. The process does not expose tools to extreme heat, so die life is longer. This reduces the frequency of tool replacement and lowers maintenance costs. Cold forging setups are ideal for high-volume production of small, precise components. Companies can achieve high precision with less investment in specialized machinery.

Operational Costs

Operational costs differ greatly between hot and cold forging. Hot forging consumes large amounts of energy to heat aluminum to the required temperature. This energy use increases utility bills and impacts the environment. The process also creates thermal stresses that can lead to die failure, adding to maintenance expenses. Despite these costs, hot forging remains valuable for producing parts with superior properties and complex geometries.

Cold forging stands out as more cost-effective. The process does not require heating, so energy costs stay low. Manufacturers can run cold forging operations continuously, making it ideal for high-volume production. The absence of heating also reduces the risk of die failure. Companies benefit from lower operational costs while maintaining high levels of precision.

Cold forging saves on energy costs.

Hot forging incurs higher expenses due to heating and die wear.

Cold forging supports efficient, high-volume production with consistent precision.

Scrap and Material Use

Material efficiency affects both cost and sustainability in forging. Hot forging often produces more scrap because the process may require trimming and additional machining to achieve the desired precision. The expansion and contraction of metal during heating and cooling can also lead to material loss.

Cold forging excels in material savings. The process shapes aluminum at room temperature, so nearly all the starting material becomes part of the finished product. Minimal waste means lower raw material costs and less environmental impact. High precision in cold forging reduces the need for secondary machining, further decreasing scrap rates.

Forging Method | Material Efficiency | Scrap Generation | Precision Impact |

|---|---|---|---|

Hot Forging | Moderate | Higher | May need extra machining |

Cold Forging | High | Low | Achieves high precision |

Mechanical Properties

Strength

Strength plays a crucial role in the performance of aluminum parts. Forging changes the internal structure of aluminum, making it stronger than cast or machined parts. Cold forging increases strength through a process called strain hardening. When aluminum undergoes cold forging, the metal’s grains become tightly packed. This structure helps the part resist deformation under heavy loads.

Hot forging also improves strength, but in a different way. The high temperature allows the grains to reform and align during the process. This change creates a uniform structure that supports both strength and ductility. While cold forging produces higher strength due to work hardening, hot forging offers a balance between strength and toughness.

The table below compares the strength and toughness of aluminum parts made by each forging method:

Property | Cold Forging | Hot Forging |

|---|---|---|

Strength | Enhanced through strain hardening | Improved toughness |

Toughness | Lower compared to hot forging | Exceptional due to refined grain structure |

Engineers often choose cold forging for parts that need to withstand high stress without bending. Hot forging works well for components that require both strength and the ability to absorb impact.

Toughness

Toughness measures how well a material absorbs energy before breaking. In forging, toughness depends on the grain structure and the process used. Hot forging stands out for its ability to create tough aluminum parts. The high temperature during hot forging causes the grains to become fine and uniform. This structure helps the part resist cracks and sudden failure.

Cold forging, while excellent for strength, does not provide the same level of toughness. The process can make the metal more brittle, especially if the part experiences repeated impacts. For applications like automotive suspension arms or aerospace fittings, manufacturers often select hot forging to ensure the part can handle shocks and vibrations.

Wear Resistance

Wear resistance describes how well a part stands up to friction and repeated use. Forging improves wear resistance by creating a dense, uniform grain structure. Cold forging produces a hard surface, which helps the part resist scratches and surface wear. This benefit makes cold-forged aluminum ideal for fasteners, pins, and shafts that experience constant movement.

Hot forging also enhances wear resistance, but the effect depends on the alloy and the finishing process. The refined grain structure from hot forging helps the part last longer under stress. However, some hot-forged parts may need extra surface treatments to reach the highest levels of wear resistance.

Cold forging creates a harder surface, improving resistance to abrasion.

Hot forging provides a strong core and can be combined with coatings for added protection.

Manufacturers consider both the forging method and the final application when choosing the best process for wear resistance.

Fatigue Performance

Fatigue performance describes how well a material can withstand repeated loading and unloading cycles before it fails. In many industries, engineers consider fatigue resistance a critical property for aluminum parts. Components in automotive, aerospace, and transportation applications often face thousands or even millions of cycles during their service life. Forging methods play a significant role in determining the fatigue strength of these parts.

The hot forging process improves fatigue performance by refining the grain structure of aluminum. Fine and uniform grains help distribute stress more evenly throughout the part. This structure reduces the likelihood of crack initiation and growth under cyclic loading. Engineers often select hot forging when they need parts that must survive harsh, repetitive stresses. For example, suspension arms and wheel hubs benefit from the enhanced fatigue resistance provided by the hot forging process.

Cold forging also affects fatigue performance, but in a different way. The process increases the strength of aluminum through work hardening. This higher strength can improve fatigue life, especially for simple shapes with smooth surfaces. However, cold forging may introduce residual stresses and surface imperfections if not carefully controlled. These factors can act as starting points for cracks, which may lower fatigue resistance in some cases.

Several factors influence the fatigue performance of forged aluminum parts:

Grain Orientation: Forging aligns the grains in the direction of applied force, which helps resist crack propagation.

Surface Quality: Cold forging produces smoother surfaces, reducing the risk of surface cracks that can lead to fatigue failure.

Residual Stresses: Improper forging parameters may leave internal stresses, which can decrease fatigue life.

Alloy Selection: Some aluminum alloys respond better to forging and offer higher fatigue resistance.

Forging Method | Typical Fatigue Strength | Key Influences | Best Applications |

|---|---|---|---|

Hot Forging | High | Grain refinement, toughness | Suspension, structural components |

Cold Forging | Moderate to High | Surface finish, work hardening | Fasteners, shafts, connectors |

Fatigue testing standards, such as ASTM E466, provide guidelines for evaluating the fatigue properties of forged aluminum. Manufacturers use these standards to ensure that parts meet safety and reliability requirements. By understanding how forging impacts fatigue performance, companies can select the best process for their specific needs.

Environmental Impact

Energy Consumption

Aluminum forging impacts the environment through its energy use. Hot forging requires significant energy because workers must heat aluminum to high temperatures. Studies from the U.S. Department of Energy show that hot forging can consume between 25 and 54 kilowatt-hours (kWh) per kilogram of aluminum, depending on the alloy and process settings. This high energy demand increases greenhouse gas emissions, especially if the electricity comes from fossil fuels.

Cold forging uses much less energy. The process shapes aluminum at room temperature, so it does not need large furnaces or extended heating times. According to research published in the journal Materials, cold forging can reduce energy consumption by up to 80% compared to hot forging. This lower energy use makes cold forging a more sustainable choice for many manufacturers.

Forging Method | Typical Energy Use (kWh/kg) | Environmental Impact |

|---|---|---|

Hot Forging | 25–54 | High emissions, more energy |

Cold Forging | 5–10 | Lower emissions, less energy |

Material Waste

Material waste also affects the environmental footprint of aluminum forging. Hot forging often produces more scrap. Workers may need to trim excess material or perform extra machining to achieve the desired shape and size. This waste increases the demand for raw aluminum, which requires energy-intensive mining and refining.

Cold forging stands out for its material efficiency. The process uses almost all of the starting material, leaving very little scrap. This efficiency not only saves money but also reduces the environmental burden of aluminum production. The Aluminum Association reports that recycling aluminum scrap saves up to 95% of the energy needed to produce new aluminum from ore.

Hot forging can generate significant waste due to trimming and finishing.

Cold forging minimizes waste, making it a greener option for high-volume production.

Choosing the Right Forging Method

Design Factors

Engineers must consider several design factors when selecting a forging method. The complexity of the part’s shape often determines the best approach. Hot forging works well for parts with intricate curves, thin walls, or unique geometries. The high temperature allows aluminum to flow into detailed molds. Cold forging, on the other hand, suits simple shapes like shafts, bolts, and fasteners. The process maintains tight tolerances and produces consistent results.

Size also plays a role. Large components often require hot forging because the process can handle more material and distribute force evenly. Small or medium-sized parts benefit from cold forging, especially when high precision is necessary. Surface finish requirements influence the choice as well. Cold forging creates smoother surfaces, which reduces the need for extra machining.

Performance Needs

Performance requirements guide the selection of the forging process. Some applications demand high strength, while others need toughness or resistance to fatigue. Hot forging improves toughness and grain structure, making it ideal for parts that face heavy loads or impacts. Automotive suspension arms and aerospace fittings often use hot forging for this reason.

Cold forging increases strength through work hardening. This method produces parts that resist deformation under stress. Fasteners, connectors, and shafts benefit from the added strength and precision. However, cold forging may reduce ductility, which can limit its use in parts that must absorb shocks.

The table below summarizes how each method meets different performance needs:

Requirement | Hot Forging | Cold Forging |

|---|---|---|

Toughness | Excellent | Moderate |

Strength | Good | Excellent |

Fatigue Resistance | High | Moderate to High |

Surface Finish | Moderate | Excellent |

Choosing the right forging method ensures the final part meets all performance expectations.

Budget and Scale

Cost and production scale influence the decision-making process. Hot forging requires specialized equipment and skilled workers, which increases initial setup costs. The process also uses more energy, raising operational expenses. However, hot forging can be more economical for large, complex parts produced in moderate volumes.

Cold forging offers lower operational costs because it does not require heating. The process uses standard equipment and extends die life, which reduces maintenance expenses. Cold forging is ideal for high-volume production of small, precise parts. Manufacturers save on raw materials and energy, making it a cost-effective choice for mass production.

Lead Time

Lead time plays a critical role in manufacturing decisions. Companies often face tight deadlines and must deliver forged aluminum parts quickly. The choice between hot forging and cold forging can impact how fast a project moves from design to finished product.

Hot forging usually involves longer lead times. Workers must heat aluminum to high temperatures, which takes time. The process also requires specialized equipment and skilled operators. Tooling for hot forging often needs custom design and fabrication. These steps add days or even weeks to the schedule. For complex parts, manufacturers may need extra time for mold development and process optimization.

Cold forging offers shorter lead times for many projects. The process works at room temperature, so there is no need for lengthy heating cycles. Standard dies and presses can shape simple parts quickly. Companies can set up cold forging operations with less preparation. High-volume production benefits from rapid cycle times and minimal downtime. Cold forging suits projects with tight delivery schedules and repeat orders.

The following table compares typical lead time factors for hot and cold forging:

Factor | Hot Forging | Cold Forging |

|---|---|---|

Tooling Preparation | Custom, time-consuming | Standard, faster |

Equipment Setup | Specialized, complex | Simple, routine |

Production Speed | Moderate | Fast |

Post-Processing | Often required | Minimal |

Overall Lead Time | Longer | Shorter |

Industry standards, such as those from the Aluminum Association and the U.S. Department of Energy, recommend analyzing lead time as part of the overall production strategy. Academic studies in Journal of Manufacturing Processes highlight that cold forging can reduce lead time by up to 30% compared to hot forging for simple geometries (source: DOI:10.1016/j.jmapro.2018.03.012).

Manufacturers must balance lead time with other factors like cost, quality, and mechanical properties. For urgent projects, cold forging provides a clear advantage. For complex or safety-critical parts, hot forging may justify a longer schedule due to superior material performance.

Aluminum hot forging and cold forging each offer unique benefits and drawbacks. Hot forging creates tough, complex parts but uses more energy and may need extra finishing. Cold forging delivers precise, strong components with less waste, though it limits shape complexity.

FAQ

What is the main difference between aluminum hot forging and cold forging?

Hot forging heats aluminum before shaping. Cold forging shapes aluminum at room temperature. Hot forging allows complex shapes and improves toughness. Cold forging creates precise, strong parts with a smooth surface.

Which forging method is better for high-volume production?

Cold forging works best for high-volume production. The process uses less energy and produces less waste. Manufacturers can create many small, precise parts quickly.

Can all aluminum alloys be cold forged?

Not all aluminum alloys suit cold forging. Alloys with good ductility, such as those in the 3xxx and 5xxx series, perform best. Harder alloys may crack or fail during cold forging.

Does hot forging always require post-processing?

Hot forging often needs post-processing. Parts may need extra machining or surface treatments to achieve tight tolerances and a smooth finish. This step ensures the final product meets specifications.

Which process offers better surface finish?

Cold forging provides a better surface finish. The process avoids oxidation and scale, resulting in smoother parts. Many cold-forged components need little or no additional polishing.

Is hot forging more expensive than cold forging?

Hot forging usually costs more due to higher energy use and specialized equipment. Cold forging saves on energy and tooling, especially for simple, high-volume parts.

How does forging affect the mechanical properties of aluminum?

Forging changes the grain structure of aluminum. Hot forging improves toughness and ductility. Cold forging increases strength through work hardening but may reduce ductility.

What industries use aluminum forging the most?

Automotive, aerospace, electronics, and consumer goods industries use aluminum forging. Each industry selects the process based on part requirements, such as strength, shape, and surface quality.