How to Choose the Right Manufacturing Process for Aluminum Parts

Selecting the right manufacturing process for aluminum parts requires careful evaluation of part geometry, production volume, cost, lead time, and technical requirements. Engineers often compare processes like extrusion, casting, rolling, forging, CNC machining, and 3D printing. Different selection methods, such as ProGeMa3 and Giachetti’s model, use matrices or logic models to weigh these factors:

Methodology | Factors Considered | Description |

|---|---|---|

ProGeMa3 | Cost, Product Geometry, Mechanical Properties, Production Volume | Uses a selection matrix to evaluate processes based on these attributes. |

Giachetti | Material, Product Geometry, Process Features, Mechanical Properties, Production Volume, Cost | Employs a fuzzy logic model for decision-making. |

Matching the process to the part’s needs ensures the best results for both quantity and quality.

Part Geometry

Shape and Complexity

The geometry of an aluminum part plays a crucial role in determining the most suitable manufacturing process. Simple shapes, such as tubes and beams, often require less intricate methods. Extrusion and sheet metal fabrication work well for these straightforward designs. Engineers select these processes because they deliver consistent results and maintain cost efficiency.

Complex shapes present different challenges. Sand casting stands out as a versatile and cost-effective method for producing intricate and detailed components. Industries like automotive and aerospace favor sand casting due to aluminum’s ability to form designs that other metals cannot easily achieve. The casting process enables the creation of internal passages and varying wall thicknesses, which are essential for parts with specific functional requirements. Cast aluminum allows for the incorporation of complex geometries, making it ideal for applications that demand detailed features.

Process Options

Selecting the right process depends on the part’s geometry. The following table compares examples of aluminum parts with simple and complex geometries and the processes best suited for each:

Geometry Type | Examples of Parts | Suitable Processes |

|---|---|---|

Simple | Tubes, rails, structural beams | Extrusion, Sheet Metal Fabrication |

Complex | Intricate shapes, detailed components | جعل, Casting, CNC Machining |

For highly complex aluminum parts, several advanced manufacturing processes offer distinct advantages:

Forging compresses heated aluminum into shape using high pressure, producing parts with superior strength and grain structure.

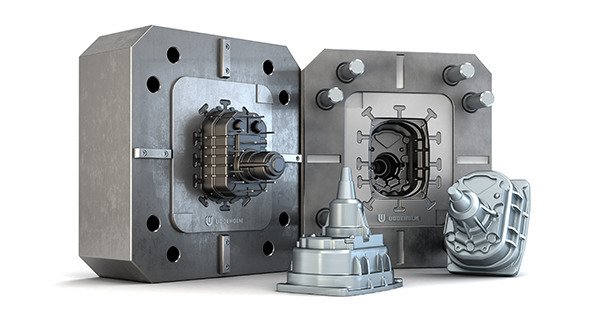

Casting pours molten aluminum into molds, enabling complex shapes and cost-effective production for high volumes.

CNC machining supports a wide range of materials and excels in creating complex geometries with tight tolerances.

Engineers often choose forging for parts that demand high strength, durability, and excellent grain structure. Casting enables complex geometries and cost-efficient production for large volumes. CNC machining delivers tight tolerances and smooth finishes for intricate details. Each process matches specific performance goals, ensuring that the final product meets both functional and quality standards.

Production Volume

Low vs. High Quantity

Production volume plays a major role in selecting the best manufacturing process for aluminum parts. When companies need only a few parts, they often choose methods with low setup and tooling costs. CNC مشینی, 3D printing, and laser cutting work well for low-volume runs, such as prototypes or custom components. These processes allow for quick changes and short lead times. TIG welding and manual bending also suit small-batch projects, especially when flexibility is important.

For mid-volume production, processes like powder metal, forging, die casting, and injection molding become more attractive. These methods balance moderate tooling costs with faster production rates. Investment casting and sand casting also fit this range, offering good surface finishes and the ability to create complex shapes.

High-volume production requires processes that can handle large quantities efficiently. Forging, Die casting, extrusion, and progressive die stamping provide high production rates and consistent quality. Automated cutting systems further improve efficiency for mass production. The table below summarizes suitable processes for different production volumes:

Production Volume | Characteristics | Suitable Processes |

|---|---|---|

Low (1-10,00) | Short lead times, low tooling costs | CNC machining, 3D printing, Laser cutting |

Mid (<10k <50k) | Moderate lead times, moderate tooling | Forging, Powder metal, Die casting, Injection molding |

High (>50k) | High lead times, higher tooling costs | Die Foriging, Die casting, Injection molding, Progressive Die |

Batch Size Impact

Batch size directly affects the cost and efficiency of each manufacturing process. When companies produce larger batches, they spread setup and tooling costs over more units. This approach lowers the cost per part and increases overall efficiency. Smaller batches, on the other hand, lead to higher per-part costs because setup and machine downtime occur more often.

For low to medium volumes, machining often provide the fastest and most cost-effective solutions.

High-volume runs benefit from processes like extrusion, Forging and Die casting, which reduce labor and material waste.

Selecting the right batch size helps manufacturers control costs and meet production goals. Companies should always match their batch size to the strengths of the chosen manufacturing process.

Manufacturing Process Selection

Cost Factors

Selecting the right manufacturing process for aluminum parts depends on several cost0-related factors. Material quality influences both durability and surface finish. Production volume plays a b major role in determining the cost per unit. Larger runs allow manufacturers to distribute setup and tooling costs across more parts, which reduces the price for each item. Design complexity also affects expenses, as intricate shapes often require advanced tooling and skilled labor.

Tooling costs vary widely between manufacturing processes. For short production runs, wood patterns may cost between $1,000 and $3,000. Aluminum patterns increase expenses to $2,000–$4,000. Permanent mold casting and injection molding require even higher upfront investments, making them suitable only for large-scale production. Manufacturers must consider these costs when choosing a process.

Costs escalate with complexity: wood patterns ($1,000–$3,000), aluminum patterns ($2,000–$4,000), and permanent mold casting.

Injection molding is the most expensive option, but it works well for light metals like aluminum.

The table below compares cost characteristics for several common manufacturing methods:

Manufacturing Method | Cost Characteristics |

|---|---|

Metal 3D Printing | High per-part cost; optimal for fewer than 100 units |

CNC مشینی | Moderate per-part cost; economical for 100–1,000 units |

Casting | Low per-part at scale (over 2,000 units); high mold/tooling upfront |

جعل | Low cost at 2,000+ units, moderate tooling, but higher unit price than casting |

Average per-part costs for CNC machining range from $30 to $500, depending on batch size and part complexity. A simple 6061 aluminum bracket may cost between $30 and $100 per part. Larger orders reduce the individual unit price, as setup and tooling costs are spread across more units.

The average cost for CNC machining aluminum parts ranges from $30 to $500 per part for small to medium-sized batches.

Costs decrease significantly for larger production volumes due to bulk order price breaks.

Factors influencing costs include part complexity, tolerances, material specifications, tooling costs, setup time, and finishing requirements.

Larger orders distribute setup and tooling costs across more units, reducing the individual unit price.

Manufacturers must weigh these cost factors when selecting a manufacturing process. The right choice depends on the balance between upfront investment, per-part cost, and production volume.

Lead Time

Lead time is a key factor in choosing between 3D printing, CNC machining, forging, and die casting. Each process has different setup requirements that directly impact project timelines.

3D printing offers the fastest turnaround, often producing parts in just a few days. CNC machining typically takes one to two weeks, depending on complexity and finishing steps. Forging requires mold design and heat treatment, with sampling usually completed in three to four weeks. Die casting involves longer tooling preparation, often extending lead times to six weeks or more before production can start.

Shorter lead times allow companies to react quickly to market changes, while processes with longer setups are better suited for stable, high-volume production. Choosing the right process means balancing speed with cost, quality, and production scale.

Tip: Always match the manufacturing process to your project’s cost, lead time, and quality needs. This approach ensures efficient production and high-quality results.

Material and Performance

Alloy Choice

Aluminum alloys come in many types, each with unique properties that influence manufacturing decisions. Engineers select alloys based on the demands of the part and the chosen process. Some alloys offer high strength, while others provide better corrosion resistance or electrical conductivity. The table below highlights common aluminum alloy series and their typical uses:

Alloy | Series | Key Characteristics | Common Applications |

|---|---|---|---|

4032 | 4000 (Al-Si-Cu-Mg) | High wear resistance, good strength, low thermal expansion | Automotive engine components, pistons, aerospace parts |

6061 | 6000 (Al-Mg-Si) | Excellent machinability, good corrosion resistance, versatile mechanical properties | Aerospace fittings, automotive parts, bicycle frames, general engineering |

6082 | 6000 (Al-Mg-Si) | High strength within 6000 series, good weldability, good corrosion resistance | Structural components, automotive chassis, bridges, offshore applications |

6063 | 6000 (Al-Mg-Si) | Excellent surface finish, good corrosion resistance, medium strength | Architectural profiles, window frames, pipelines, heat sinks |

7050 | 7000 (Al-Zn-Mg-Cu) | Very high strength, excellent toughness, good stress corrosion resistance | Aerospace structures, military vehicles, high-performance automotive |

7075 | 7000 (Al-Zn-Mg-Cu) | Extremely high strength, less corrosion resistant, lower weldability | Aircraft components, defense equipment, high-performance sports equipment |

Engineers often choose 7075 aluminum for critical structural parts because of its high strength. The 7050 series stands out for toughness and corrosion resistance, especially in thick sections. The 8000 series serves specialized needs, such as electrical wiring, due to its conductivity. Nearly pure 1XX.X alloys resist corrosion and work well in electrical and chemical environments. The 2XX.X series provides strength and hardness for load-bearing structures.

Selecting the right alloy also affects machinability and finishing. Some alloys, like 6061, machine easily and accept a wide range of surface treatments. Others may require special tools or adjustments to cutting speeds and feeds. The choice of alloy impacts not only the final part’s performance but also the efficiency of the manufacturing process.

Mechanical Properties

Mechanical properties play a key role in process selection. Strength, corrosion resistance, weldability, and machinability all influence which manufacturing method works best. The table below summarizes important properties and their impact:

Mechanical Property | Importance in Manufacturing Process |

|---|---|

Strength | Ensures durability and load-bearing capacity |

Corrosion Resistance | Extends part life in harsh environments |

Weldability | Allows joining of components without defects |

Machinability | Simplifies shaping and finishing |

Thermal Properties | Maintains stability under temperature changes |

Different manufacturing processes can change these properties. Hot extrusion increases ductility by altering the microstructure, making parts easier to form but sometimes reducing strength. Cold extrusion improves hardness and strength, resulting in parts with tighter tolerances and better surface finishes. The cooling rate and any heat treatments further control the final properties of the aluminum part.

Tip: Always match the alloy and process to the required mechanical properties. This approach ensures the finished part meets both performance and quality standards.

Secondary Operations

Machining Needs

After primary manufacturing, most aluminum parts require additional machining to achieve precise dimensions and functional features. Machining operations such as drilling, milling, and turning help create holes, threads, and complex shapes that casting or extrusion alone cannot provide. CNC machining offers high precision and control, making it possible to produce intricate designs and tight tolerances. Many manufacturers also use engraving to mark parts with lot numbers or identification codes, which supports traceability and quality control.

Common secondary machining steps include:

Deburring: Removes sharp edges and small imperfections, improving safety and appearance.

Trimming: Eliminates excess material, such as flash from casting or extrusion.

Punching and drilling: Adds holes or slots for assembly or mounting.

Sub-assembly: Joins separate components before final assembly.

The choice of manufacturing process often depends on the expected post-processing. For example, additive manufactured aluminum parts may need more intensive machining to improve surface quality, while cast parts might require different cutting conditions due to their microstructure.

Aspect | Additive Manufactured (AM) AlSi10Mg | Cast AlSi10Mg |

|---|---|---|

Machinability | Different cutting conditions | |

Surface Finish | Better due to smaller grain size | Generally poorer |

Finishing Needs

Finishing steps enhance both the appearance and performance of aluminum parts. Surface treatments protect against corrosion, increase wear resistance, and improve durability, especially in demanding environments like automotive or aerospace.

Typical finishing operations include:

Anodizing (Type II/III): Increases corrosion resistance and is widely used for general aluminum parts.

Powder coating: Adds a durable, colorful finish, ideal for outdoor and automotive applications.

Bead blasting: Conceals machining marks and creates a uniform matte surface.

Chemical conversion coating: Prepares surfaces for painting.

Electroplating: Provides decorative and protective coatings, often used in electronics.

Hard anodizing: Boosts wear resistance for high-stress parts.

Electrophoresis (e-coating): Delivers a uniform coating, especially for die-cast parts.

Polishing and sanding: Refines the surface for a smooth finish.

If your product requires anodizing or hard anodizing, forging or CNC machining are the most reliable choices. Both create dense, uniform structures that minimize porosity, ensuring consistent color and strong corrosion resistance.

For parts that only need painting, powder coating, or electrophoresis, casting can be a cost-effective option. These coatings can cover surface imperfections and deliver durable protection, even when the base material has porosity.

When decorative finishes such as polishing or plating are important, CNC machining offers the highest flexibility. Smooth tool-controlled surfaces can be easily refined and prepared for high-quality cosmetic coatings.

In short, anodizing works best with forging and CNC machining, while casting is better matched with coatings that hide or seal the surface. The finishing requirement should guide your choice of manufacturing process.

Selecting the right aluminum manufacturing process depends on several key factors:

Application requirements, such as yield and tensile strength

Processing compatibility with the chosen alloy

Cost considerations and budget limits

Common mistakes include ignoring material properties, overlooking tolerances, and poor design for manufacturing. Consulting with experts provides access to advanced technology, material knowledge, and skilled troubleshooting. Manufacturers can also benefit from resources like Processing 101, industry standards, and technical design guides. Engaging with suppliers helps manage residual stresses and machining quality. At Huatuchang, we provide one-stop solutions—from DFM support and tooling to forging, CNC machining, surface treatment, and final delivery, helping you bring complex aluminum components to market with confidence.

FAQ

What is the most cost-effective process for making simple aluminum parts?

Extrusion often provides the lowest cost for simple shapes like tubes or beams. This process uses minimal tooling and produces consistent results. Manufacturers choose extrusion for high-volume production and straightforward designs.

Can 3D printing produce strong aluminum parts?

3D printing creates aluminum parts with good strength, especially when using alloys like AlSi10Mg. However, traditional methods such as forging or die casting usually deliver higher mechanical properties for demanding applications.

How does alloy selection affect manufacturing?

Alloy choice impacts machinability, strength, and corrosion resistance. For example, 6061 aluminum machines easily and accepts many finishes. Engineers select alloys based on part requirements and the chosen manufacturing process.

What finishing options improve corrosion resistance?

Anodizing increases corrosion resistance and durability. Powder coating adds a protective layer and color. Both methods extend the lifespan of aluminum parts, especially in outdoor or harsh environments.

Is CNC machining suitable for prototypes?

CNC machining works well for prototypes and small batches. This process offers high precision, quick turnaround, and flexibility for design changes. Manufacturers often use CNC machining to test new designs before mass production.